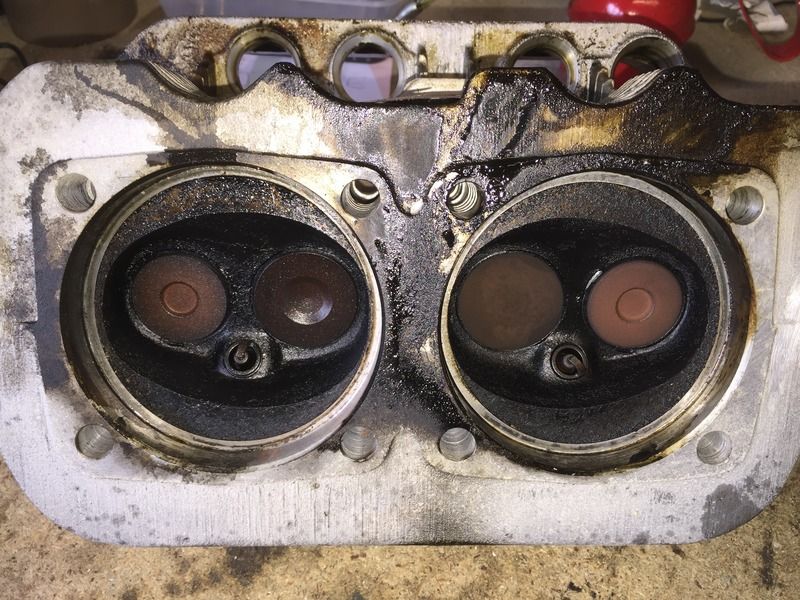

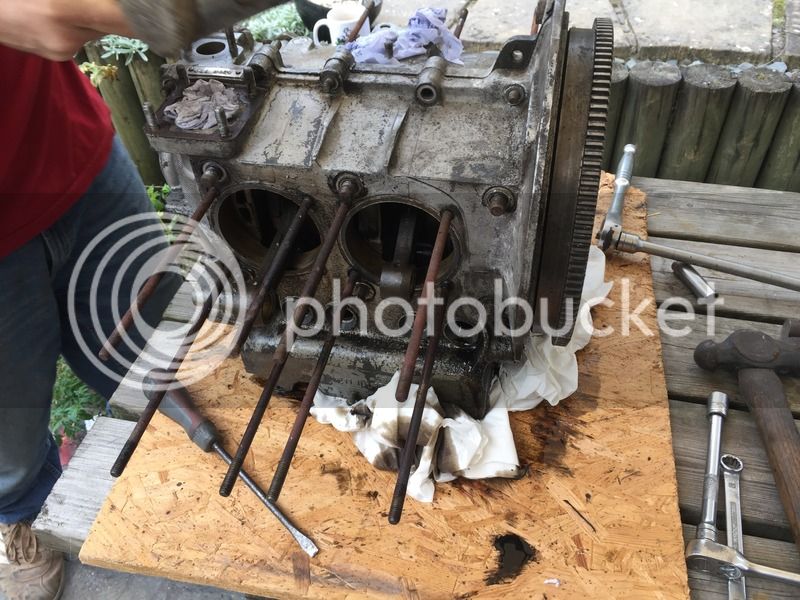

Needed to get the other head off too

URL=http://s35.photobucket.com/user/misterscoops/media/SuperDry/ADA5168D-5155-4049-9B82-36AD95D818E1_zpszk89pkex.jpg.html]

[/URL]

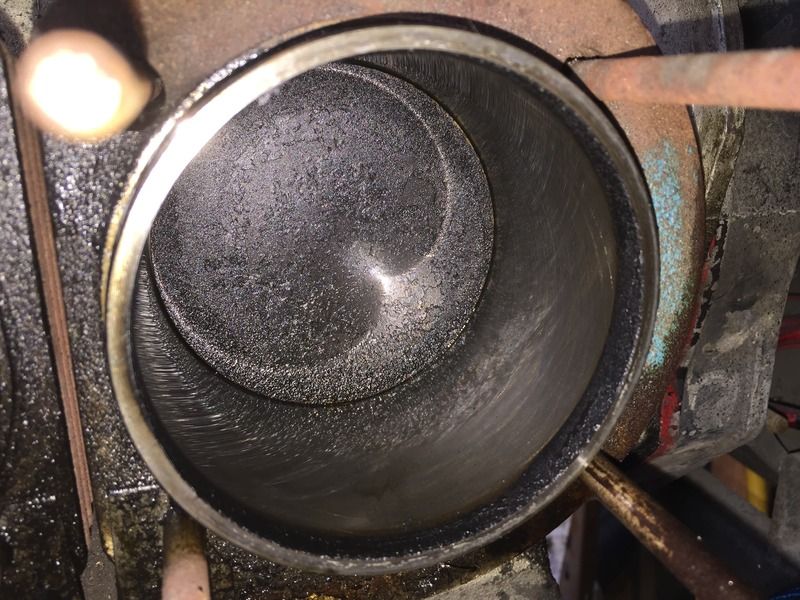

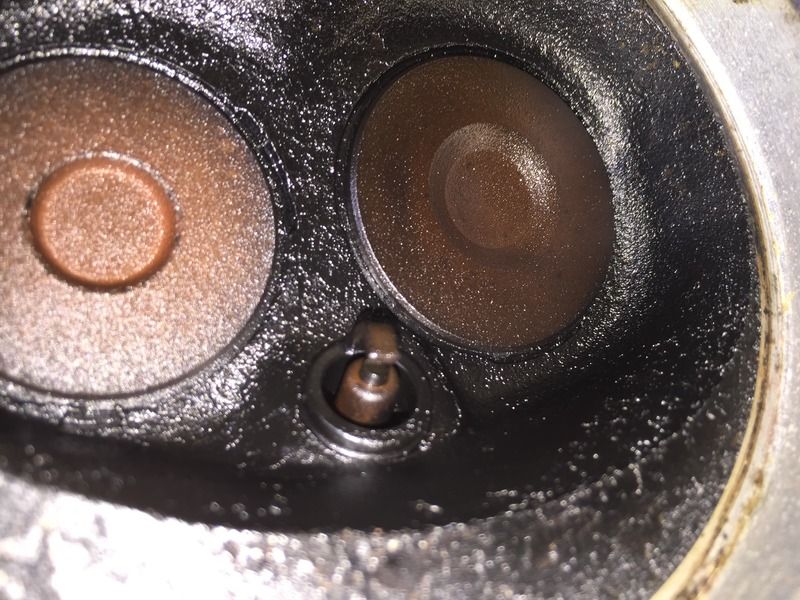

This side looked healthier so I'm assuming it had been tipped on it's side at some point.

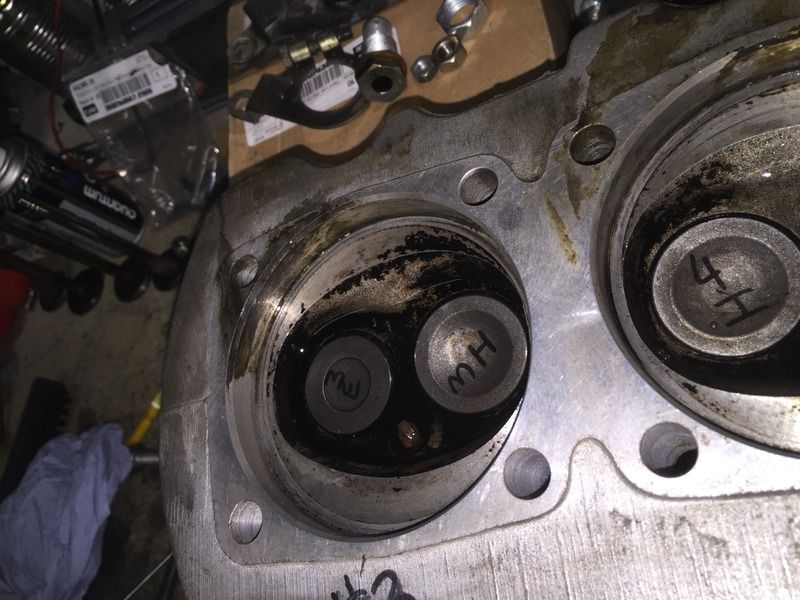

Marked up and ready for some diagnosis from Nomates

Plugs look better this side too

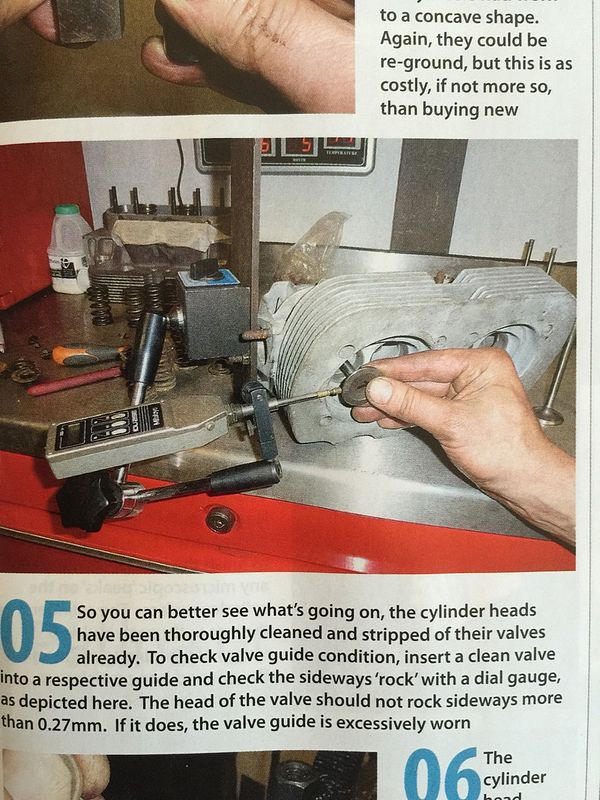

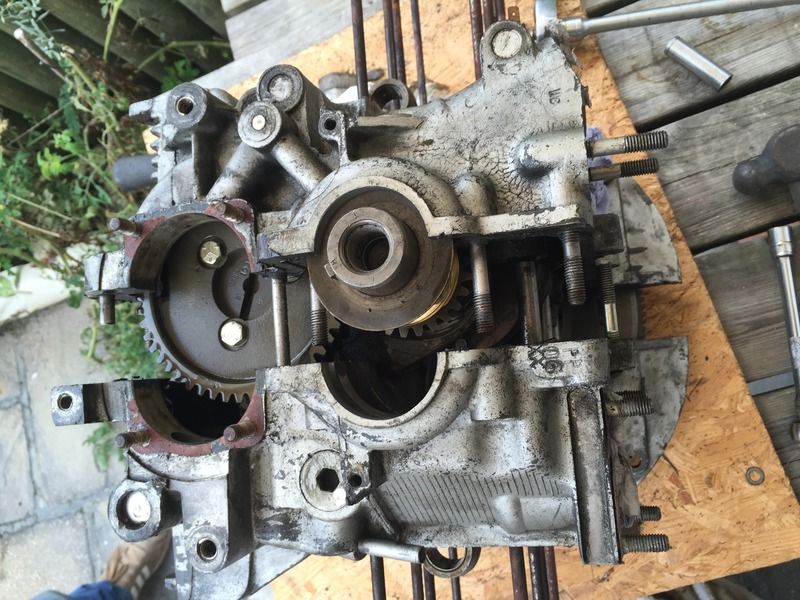

Armed with some measuring data I set off to Dr Nomates Engine Emporium.

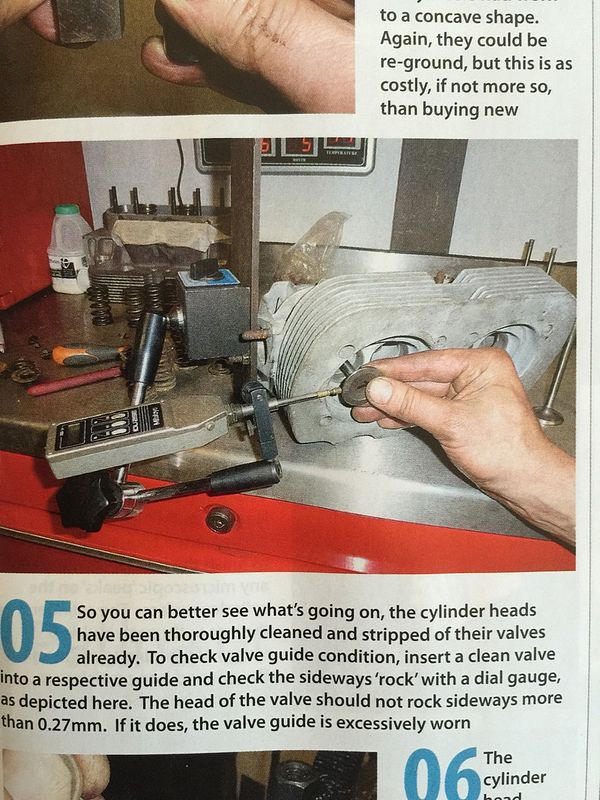

However, Dr Nomates shunned this info in his own special way by saying "that's bollocks, they are showing you measure the guide wear from side to side, they wear top to bottom" so we dismissed the article and he worked his magic.

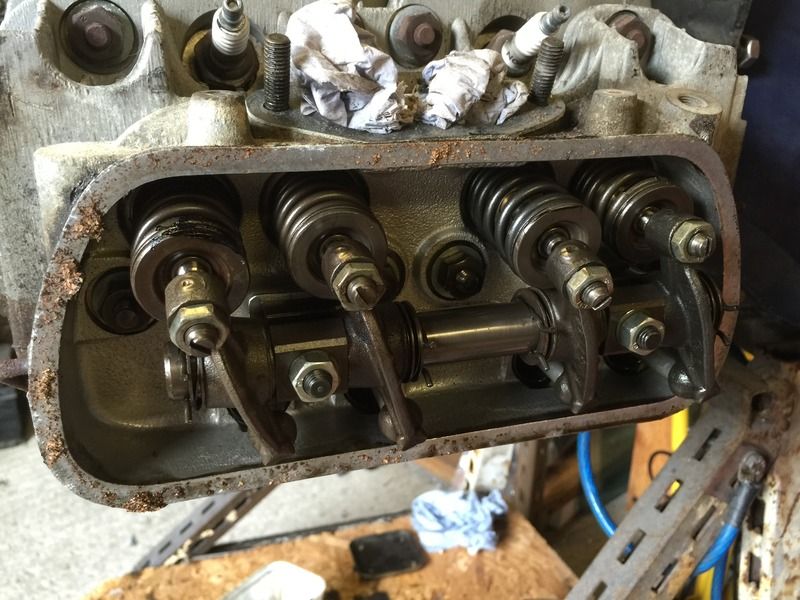

Out came the collets and springs.

And he used his in built 'spidey sense'

He said in his opinion all the guides were ok but to relap in the valves, something I'd planned to do anyway.

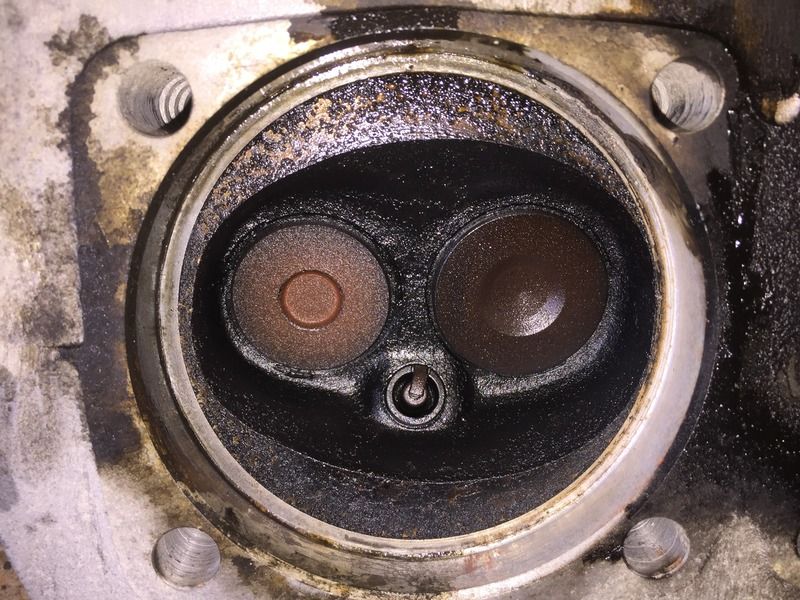

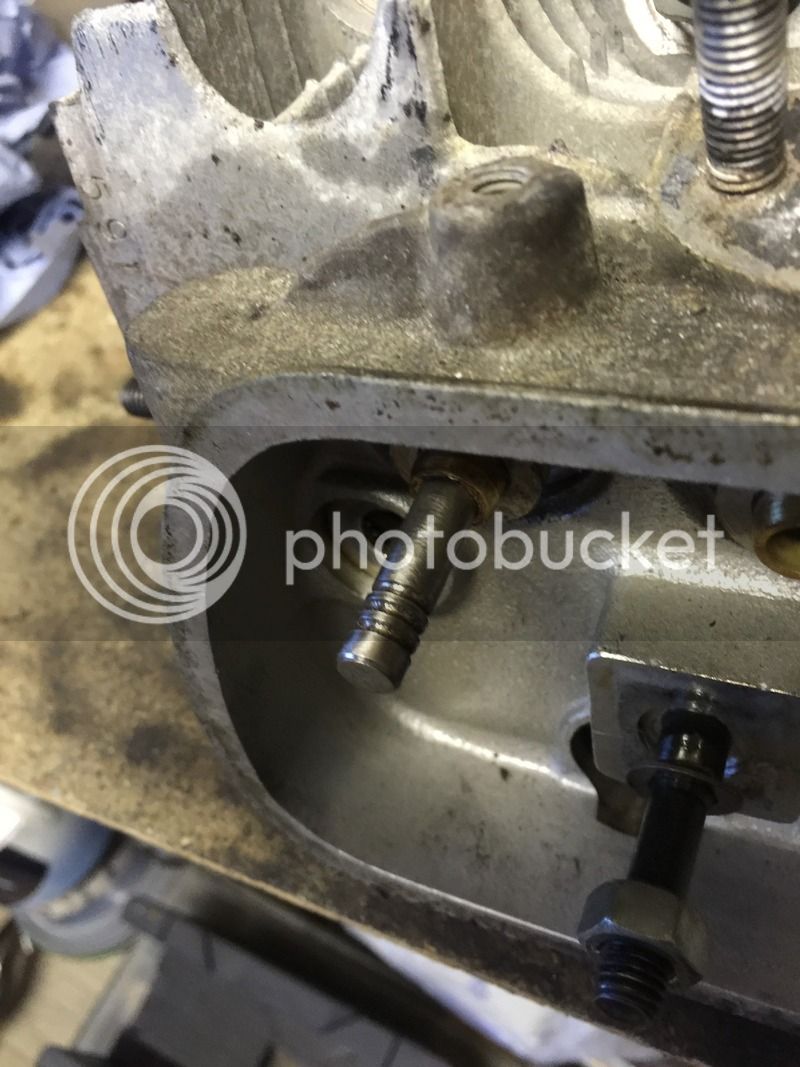

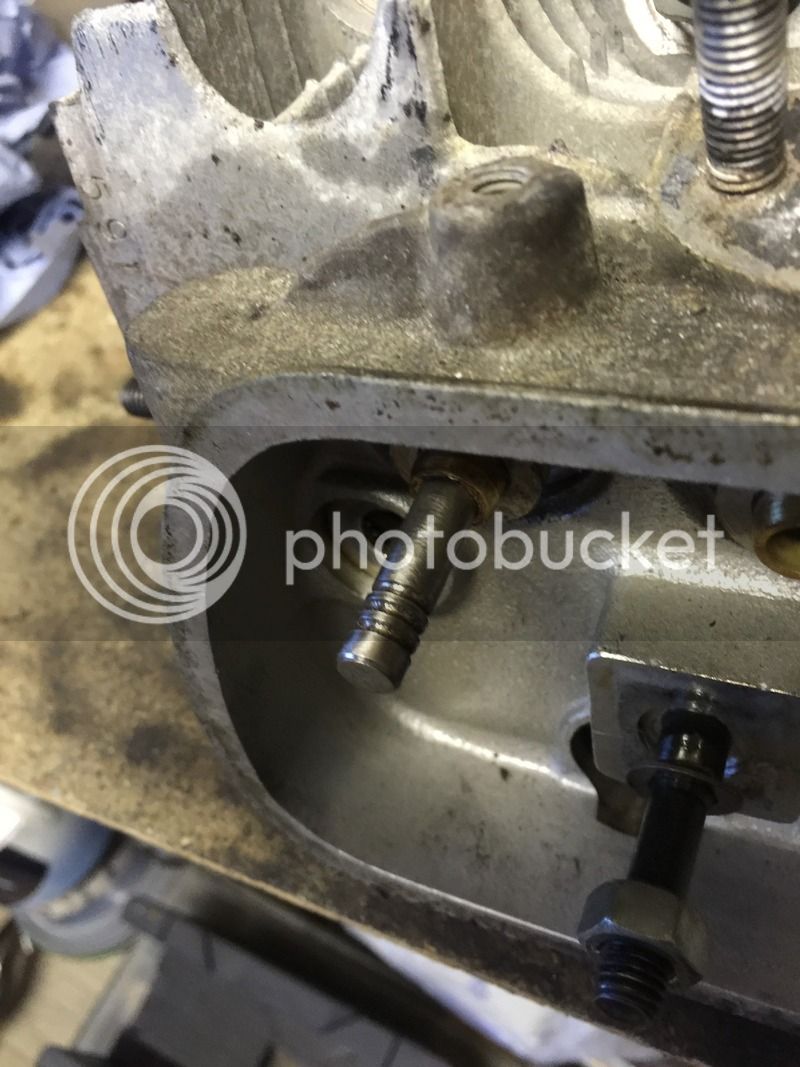

Then we had a minor issue in that the exhaust valve on Number 3 had developed a bit of a burr from the collet and wouldn't go back down the guide. The first groove had an edge on it and I didn't want to bugger the guide up by forcing it.

Out with the cutting discs in the Dremel

Ooooh, pretty

Valve cut and a chamfer put on to make sure the guide didn't get scored when it came out.

Time to start clearing the drawers out and getting stuff installed!

Problem valve replaced

Along with the others

Just need lapping in now.