Decided I was going to have a pop at doing the valve guides myself rather than farm it out;-

Both heads were coked up so the first job was to clean them up.

Bit of wire brushing and some elbow grease.

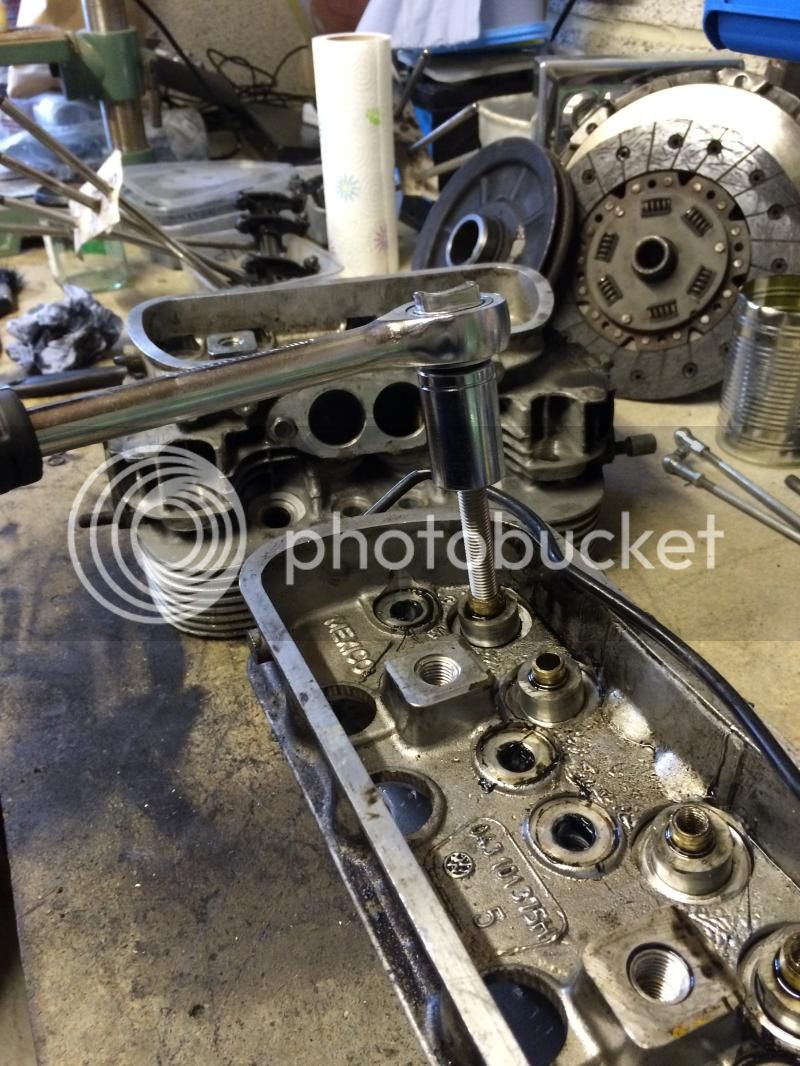

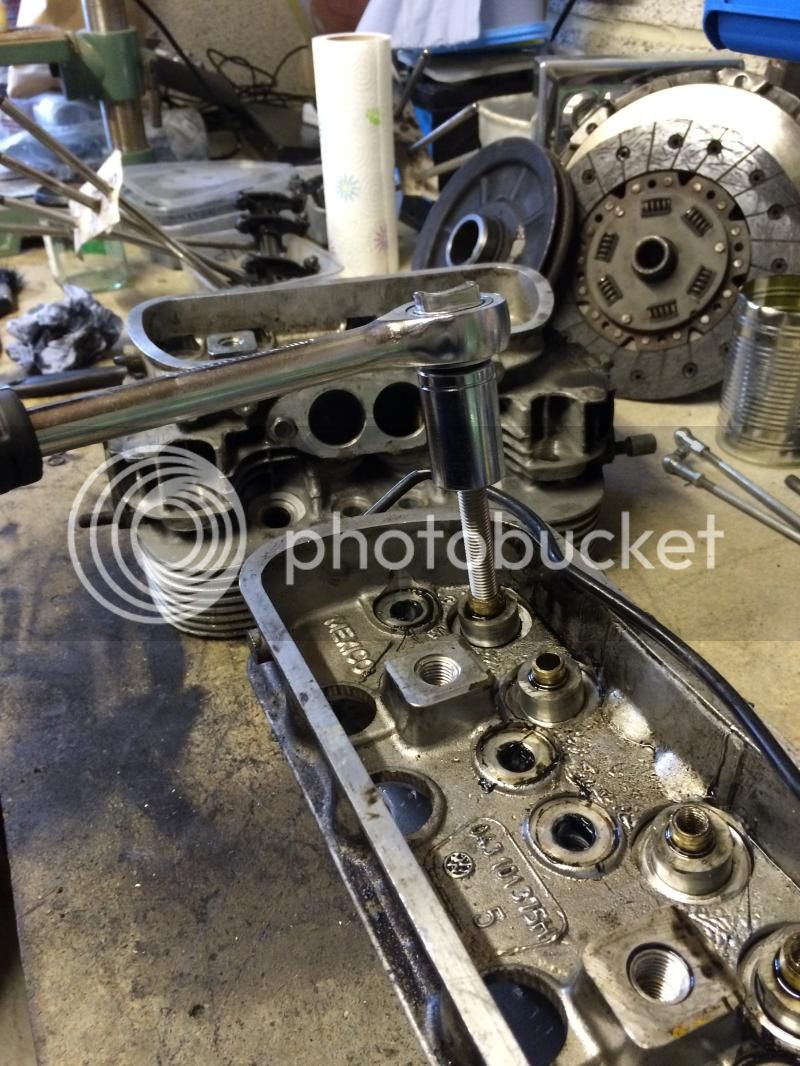

Now to get those guides out.

Still had the guide seals in situ, quite unusually!

Double nutted to get the rocker assembly studs out.

Gave me a bit more space

Threaded the guides (although my tap was crap so I popped up to a Buddies and he sorted me out, so to speak).

Put a bolt in to the newly cut thread.

Flip the heads over and you can see the bottom of the bolt that's been wound in.

Then using an old valve in the guide, tap the valve against the bolt to knock the guide out.

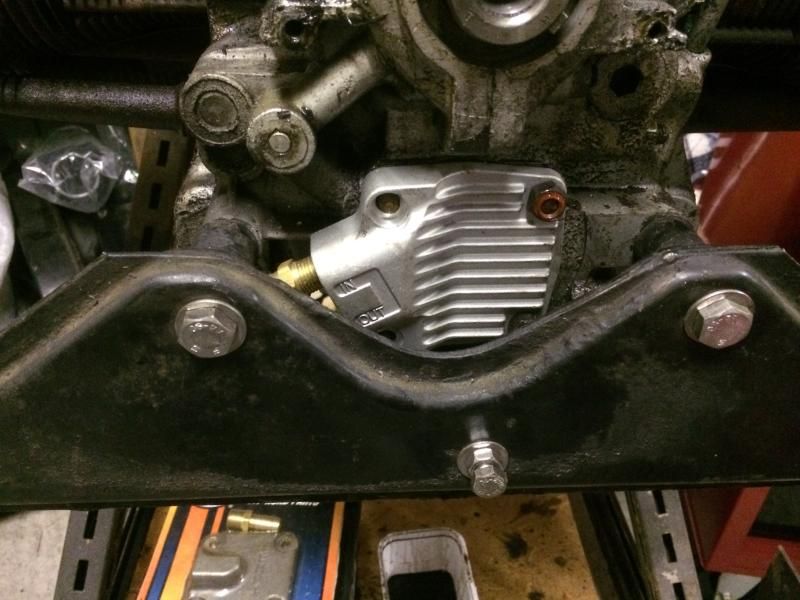

Needed a drift for the inlet valve guides as they seem to a smaller dia.

Thanks again to Nomates and his lathe.

Replace the old valve with the drift and twat it!

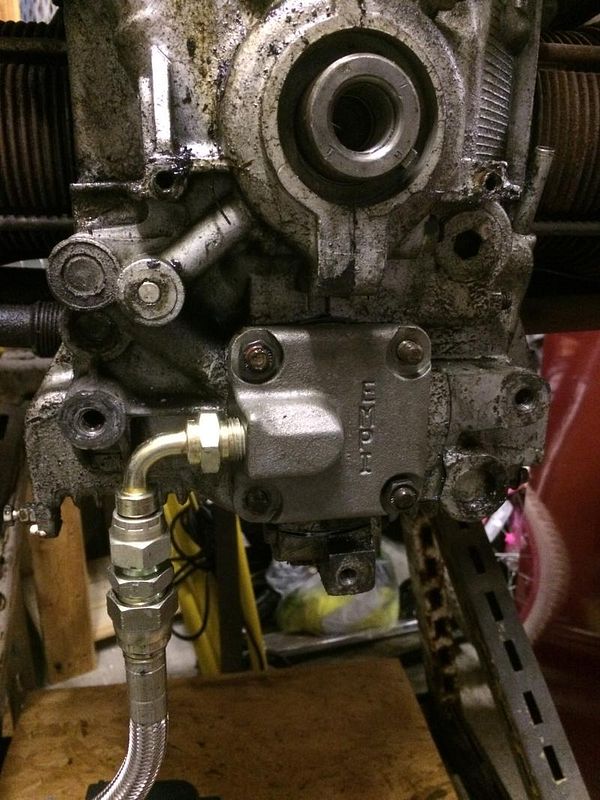

Managed to get them all out. And as you can see, the inlet and exhaust guides are definitely different sizes. I'll have to call Machine7 tomorrow to return 4 of the guides and see if they have the correct size in stock.

Had a couple of issues though. Had to use a socket as well on the end of the drift to push out a guide, however, I didn't realise it had made contact with the valve face.

And also managed to peen a bit of the guide over too.

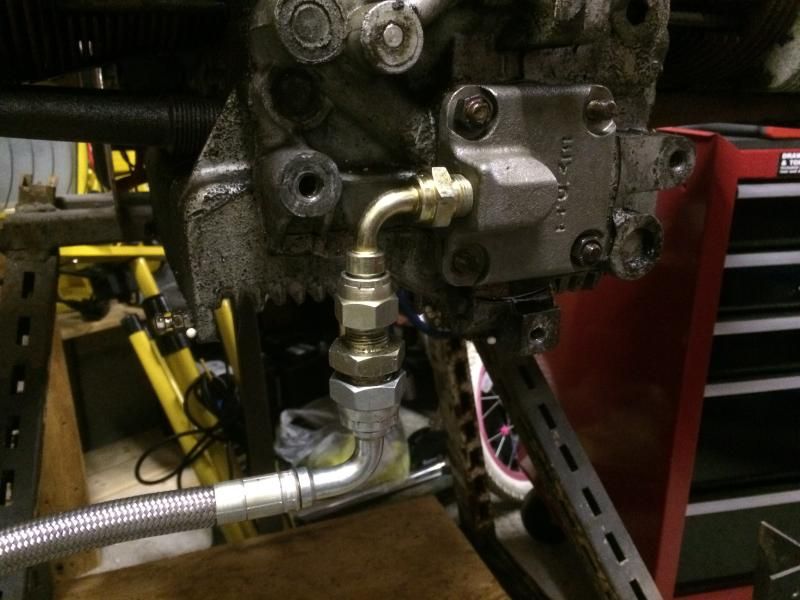

So. I may have written off one of the heads with the damage to the valve face and the guide hole. Going to take it somewhere to see if it is salvageable.

Arse, still, a lesson learned for next time. Get some longer drifts made up.