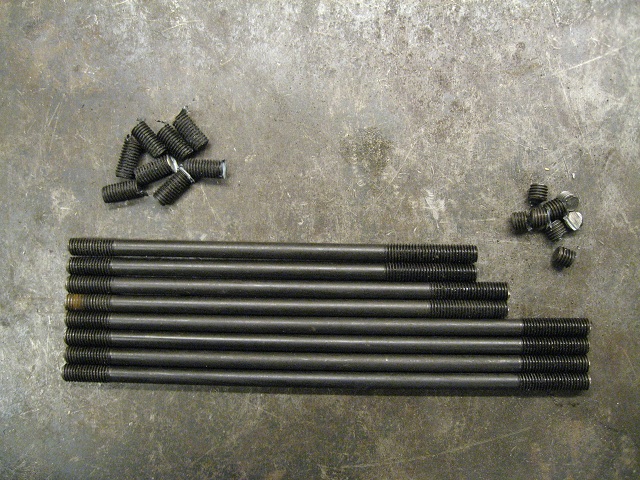

tmatre said:Got a mail from VWParts yesterday.. parts shipped

Exciting times ahead :mrgreen:

tmatre said:Got a mail from VWParts yesterday.. parts shipped

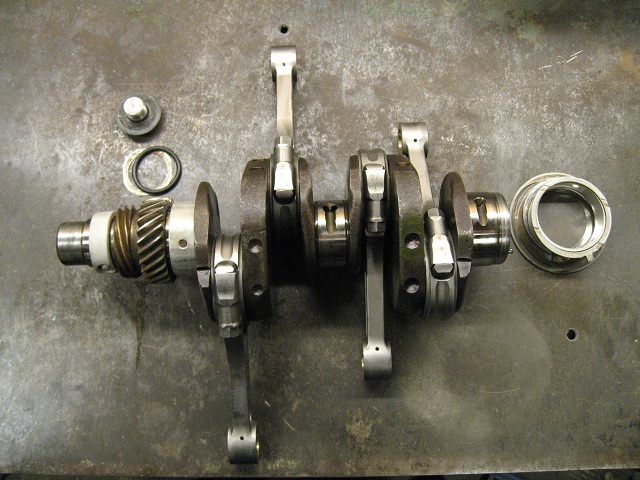

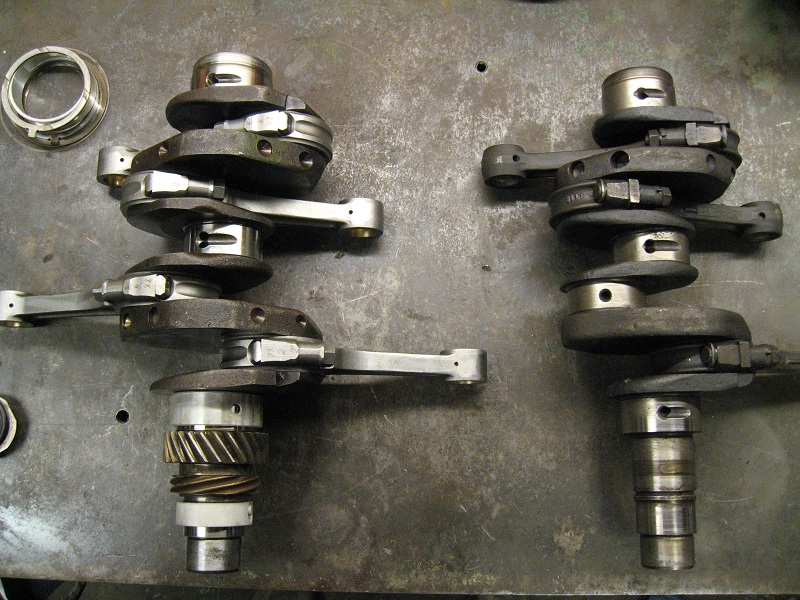

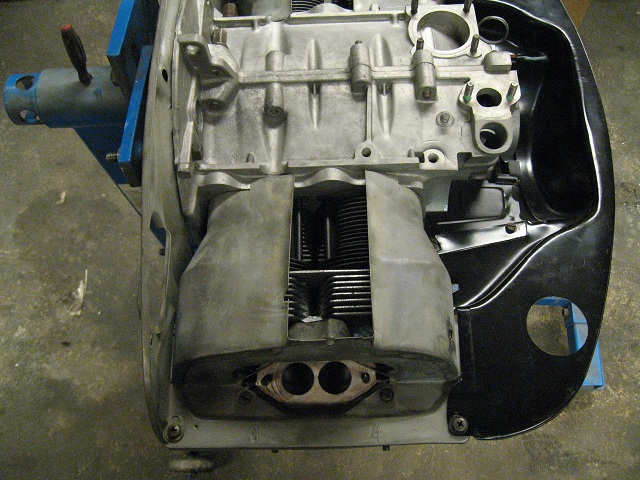

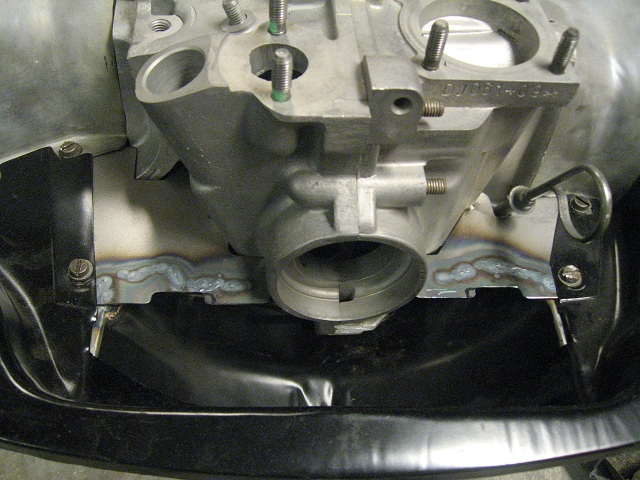

Airtime said:This will be an awesome engine! :shock: 8)

Great job on your home made continental bed! 8)

gninnam said:That canoe look fantastic 8)

Any pics of that being made :mrgreen:

Enter your email address to join: