You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Campervan conversion

- Thread starter joaonar

- Start date

Help Support Early Bay Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

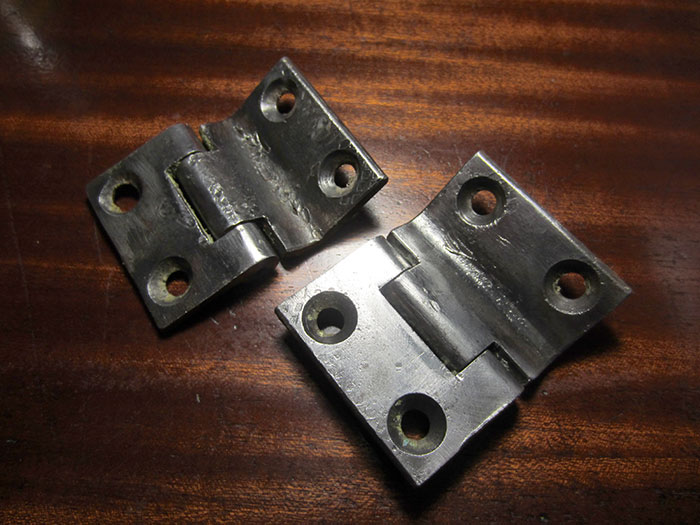

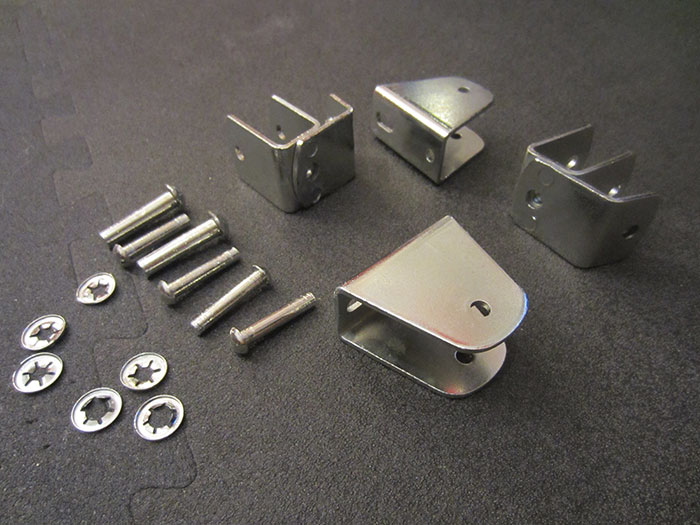

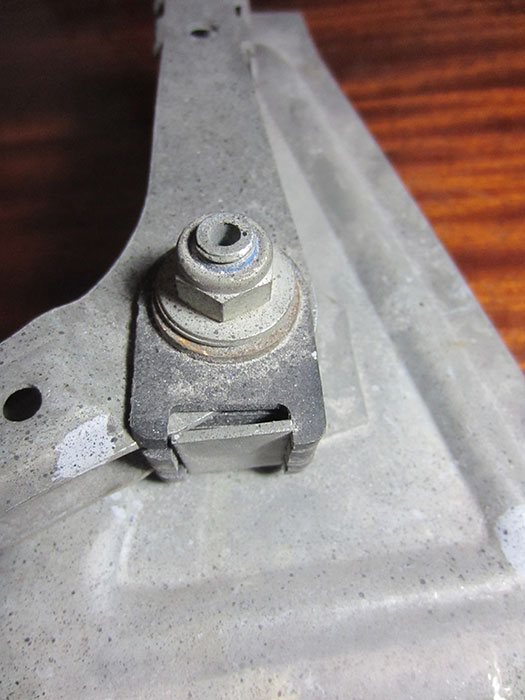

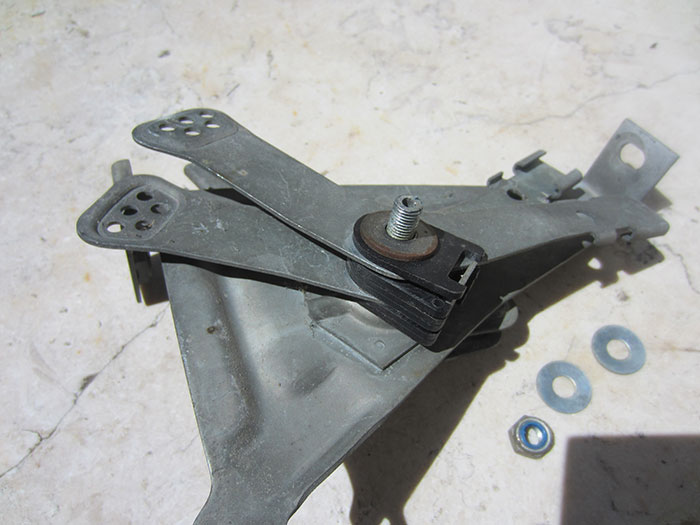

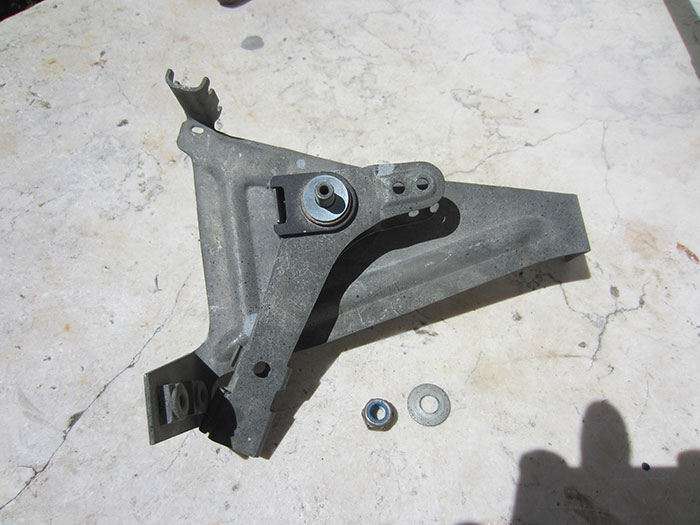

Other task to do: clean all paint and rust prevention treatment from these screws.

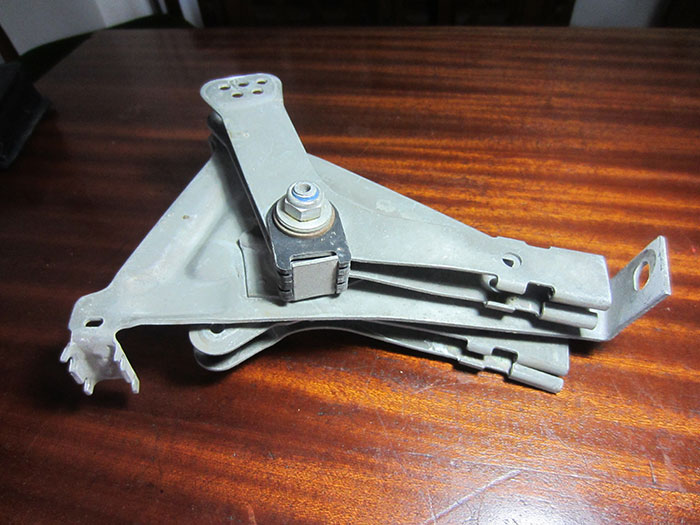

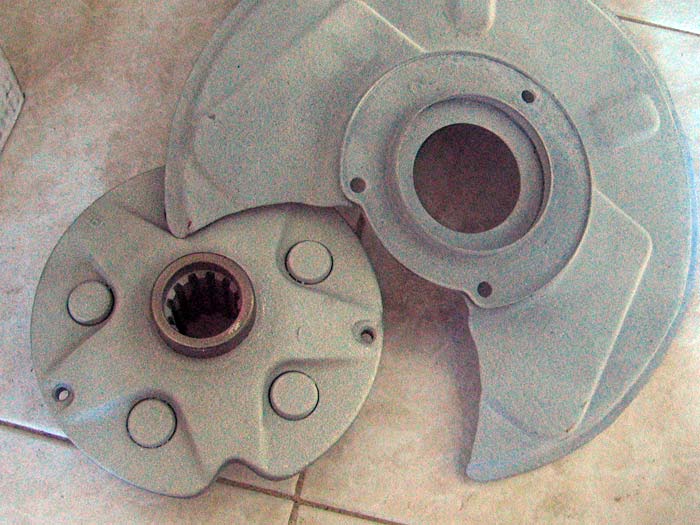

It was a stupid decision to metallize the central hub with the bolts in it. The excessive amount of metal from the anti-rust treatment and the excessive paint will make the nuts almost impossible to fasten.

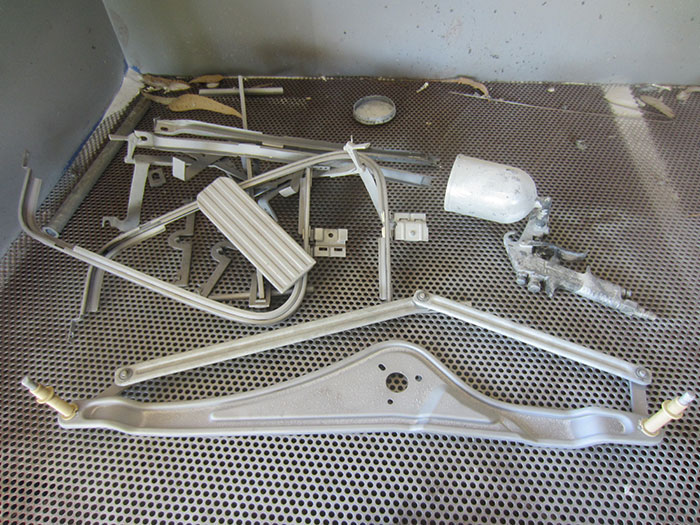

In 2008 after sending some parts to metallize...

and after painting them, in 2012::

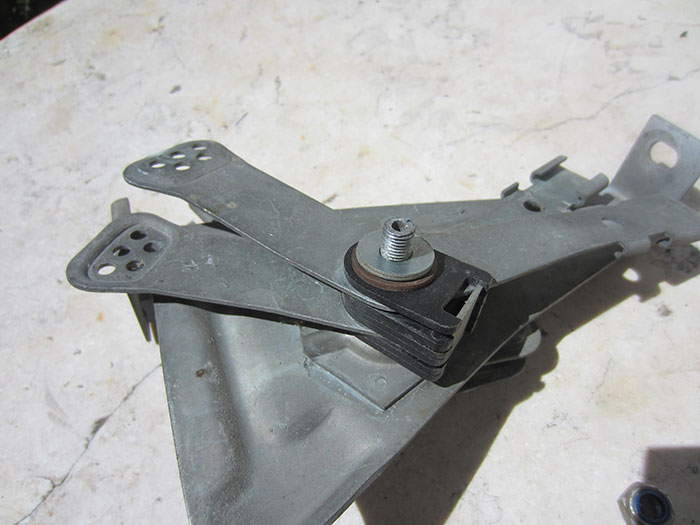

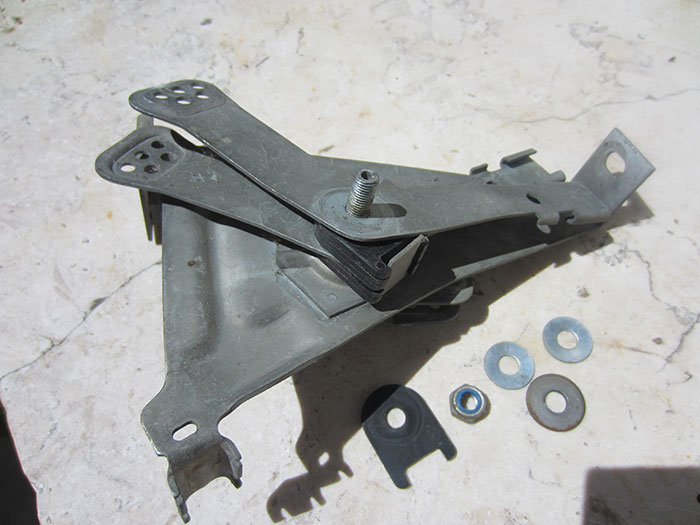

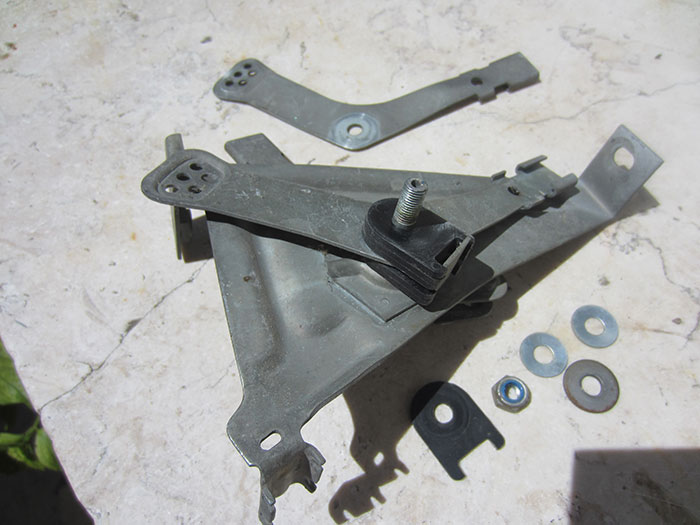

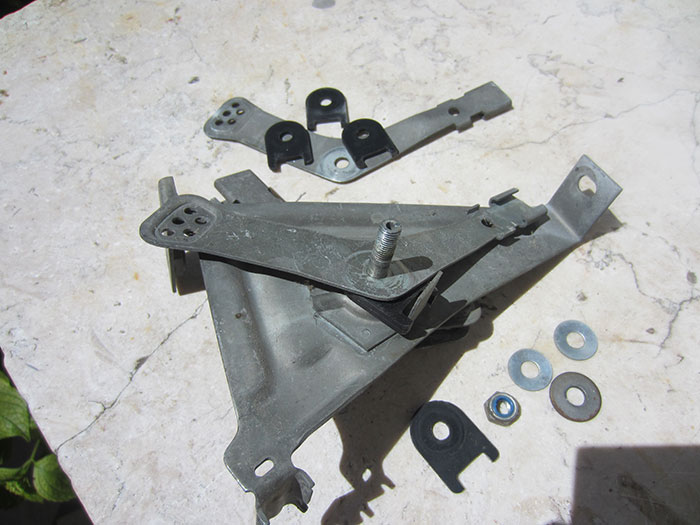

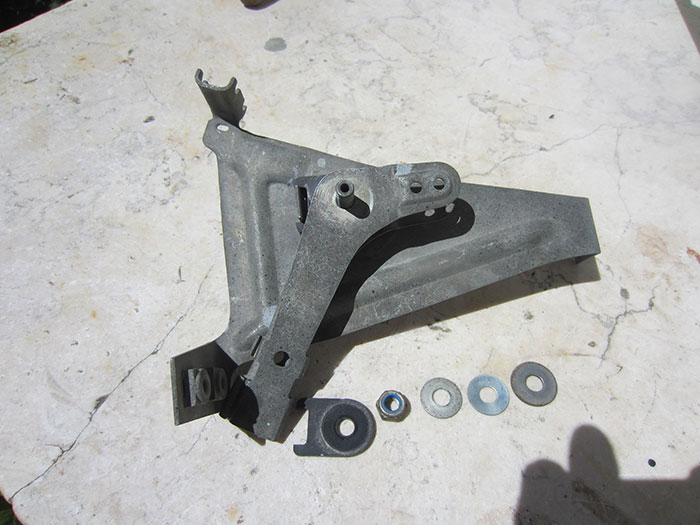

So, first I use some paint stripper:

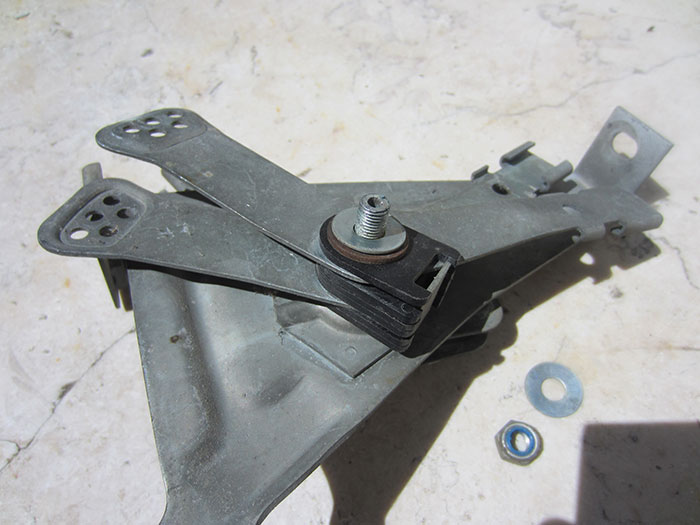

... and after using a wire wheel brush:

but they will not be like this in the end....

It was a stupid decision to metallize the central hub with the bolts in it. The excessive amount of metal from the anti-rust treatment and the excessive paint will make the nuts almost impossible to fasten.

In 2008 after sending some parts to metallize...

jnar said:(...)

and after painting them, in 2012::

jnar said:(...)

So, first I use some paint stripper:

... and after using a wire wheel brush:

but they will not be like this in the end....

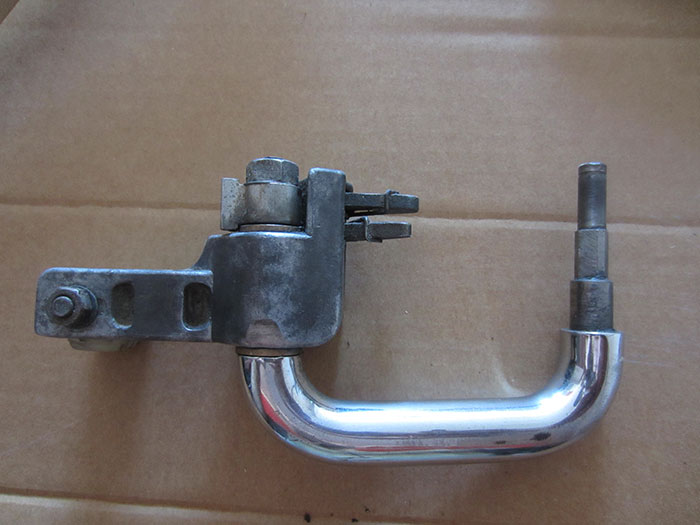

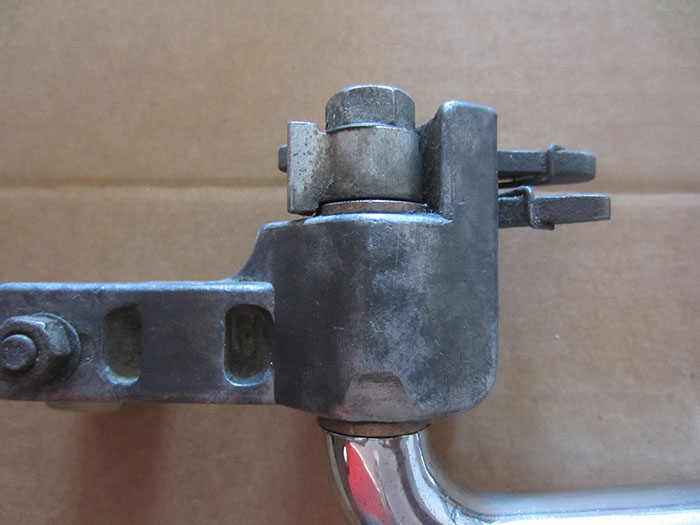

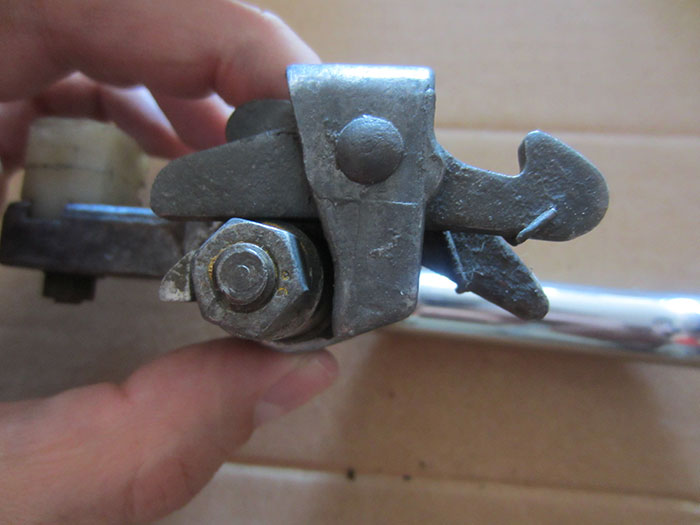

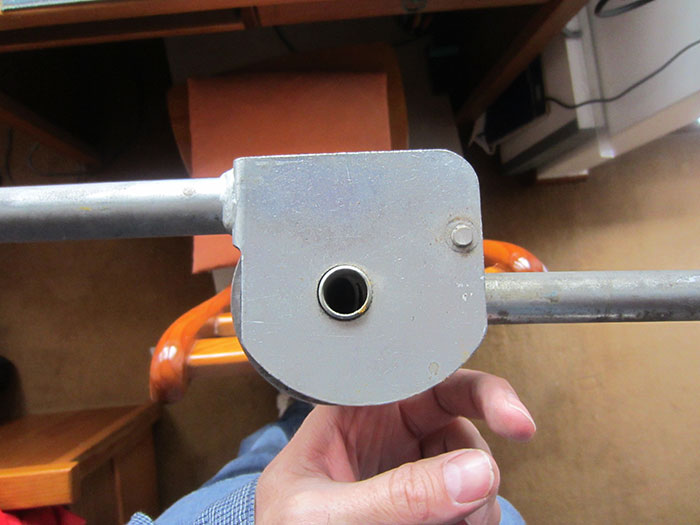

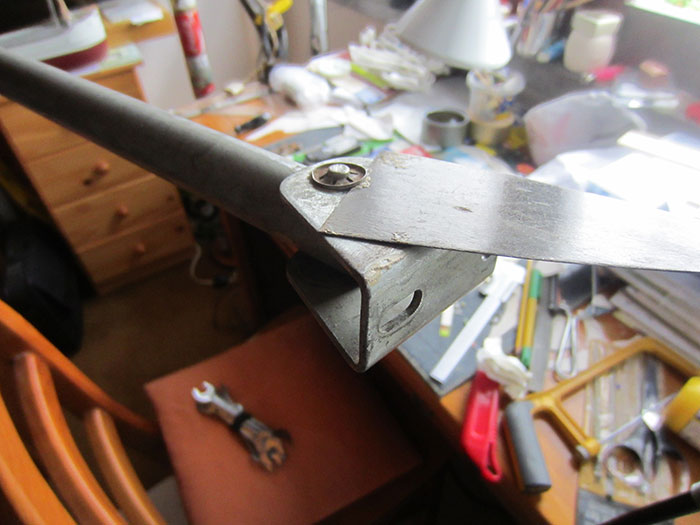

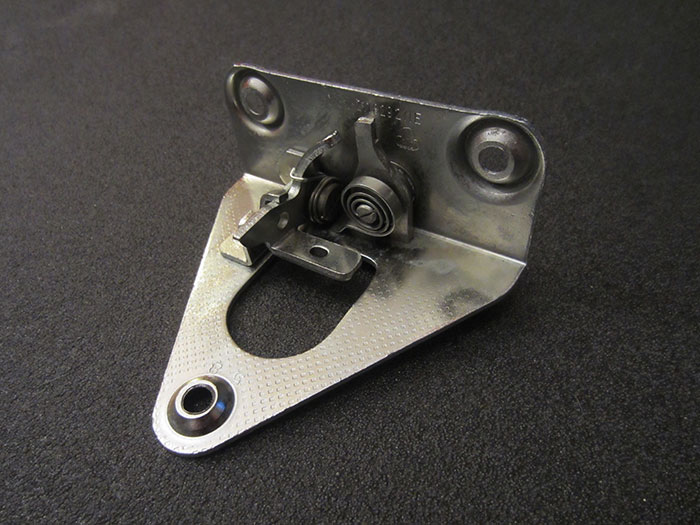

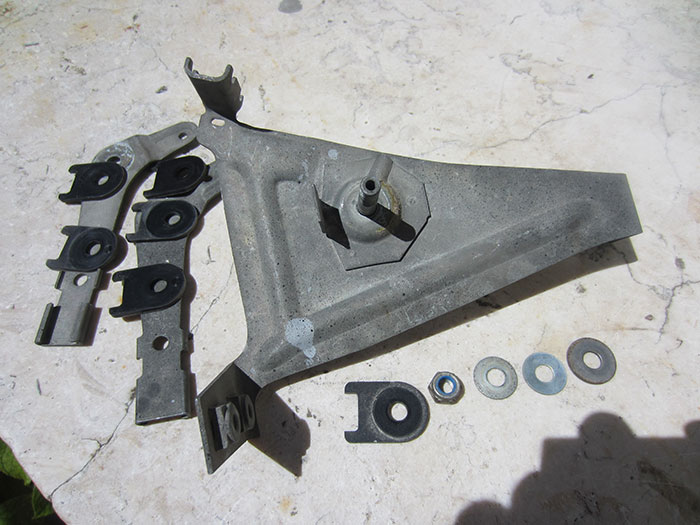

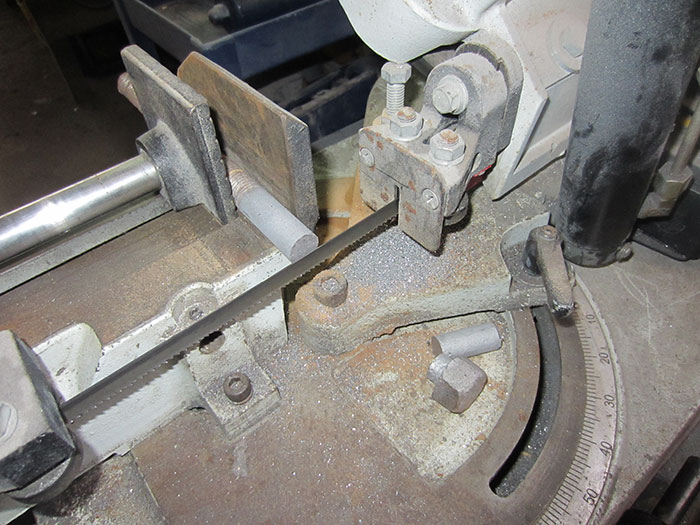

... while inside the bodyshop, Hugo was fixing this part from the poptop roof inner support. After several years of use, the central tube was starting to be cuted by another part from the support itself.... literally cuted! :shock:

However, witth all the tubes cleaned, this structural flaw became noticed. When I assembled it again I realized that this cut was getting really deep, so I had to fix it before all the support would break in the future and while in use.

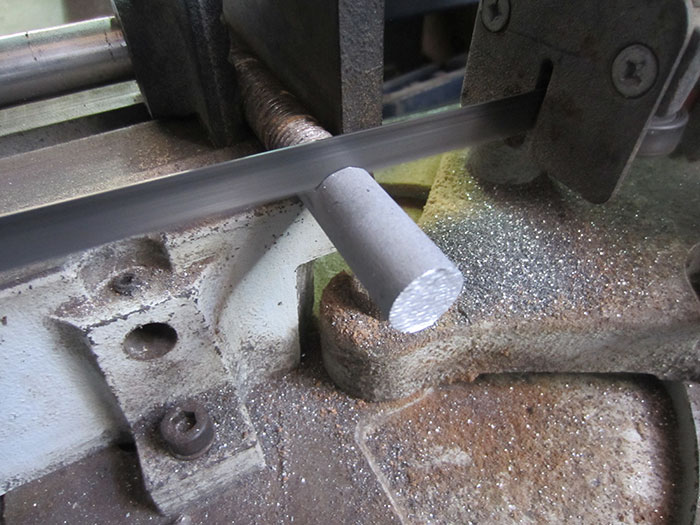

First, Hugo needed to clean the inside of the tube:

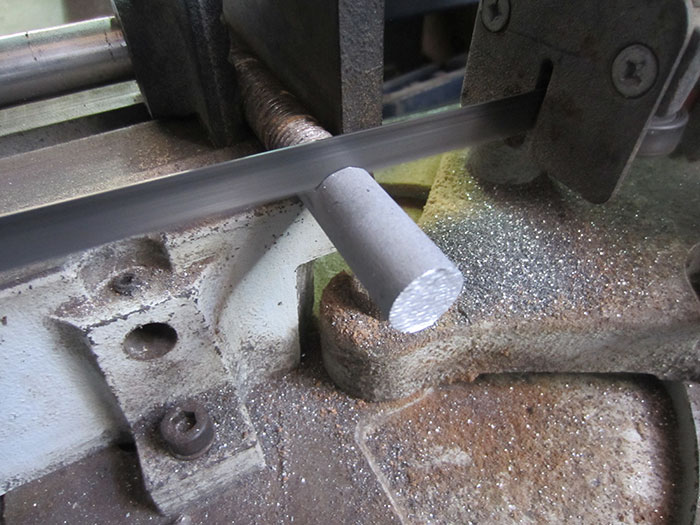

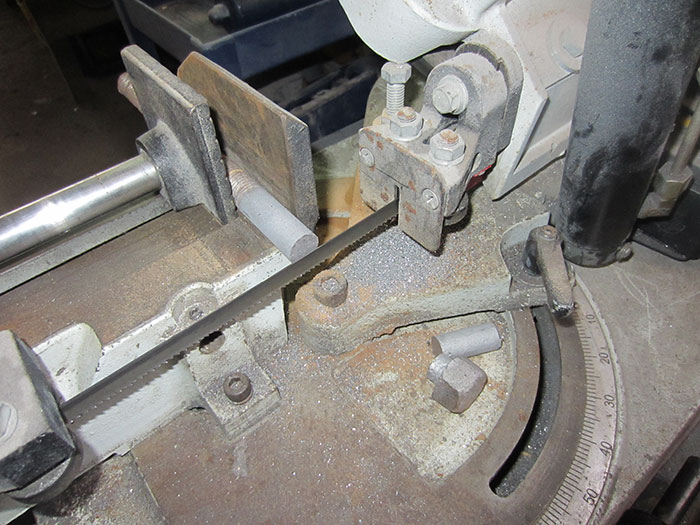

... and then, using a rod with the same diameter as the inner side from the original tube, he cuted two small pieces, one for each side of it:

However, witth all the tubes cleaned, this structural flaw became noticed. When I assembled it again I realized that this cut was getting really deep, so I had to fix it before all the support would break in the future and while in use.

First, Hugo needed to clean the inside of the tube:

... and then, using a rod with the same diameter as the inner side from the original tube, he cuted two small pieces, one for each side of it:

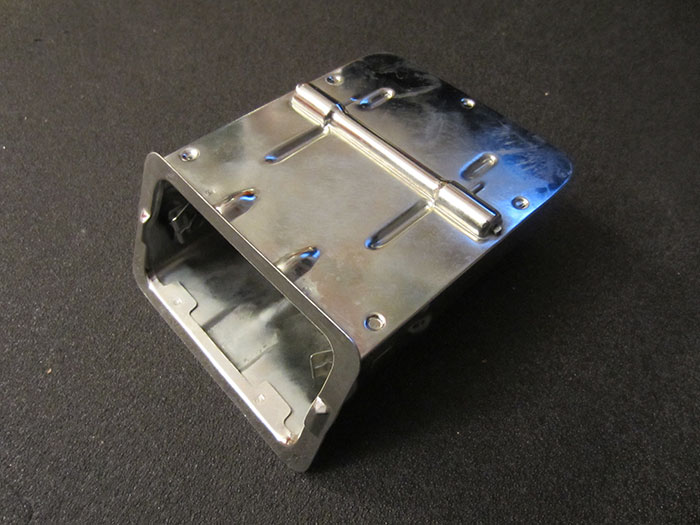

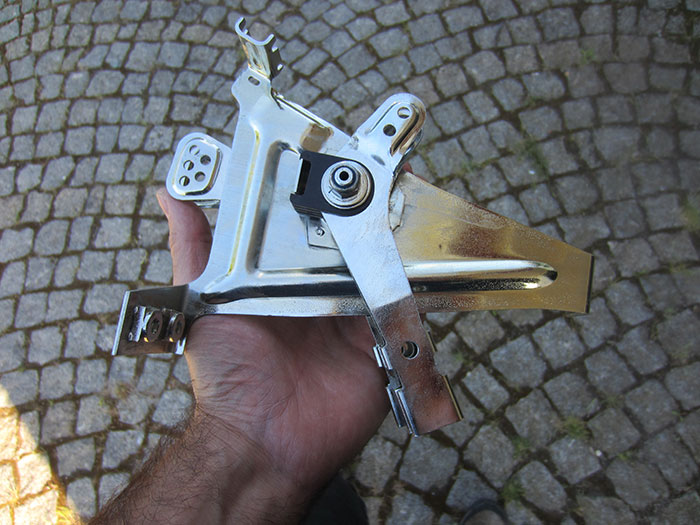

Once again at the place where the bus is, it was LEGO time. It's a very satisfying task but at the same time it can be a really desperate one. This is because it feels good to assemble cleaned and almost new parts in a bus painted fresh but trying to find the correct bolts and nuts can be a really desperate task :mrgreen: :

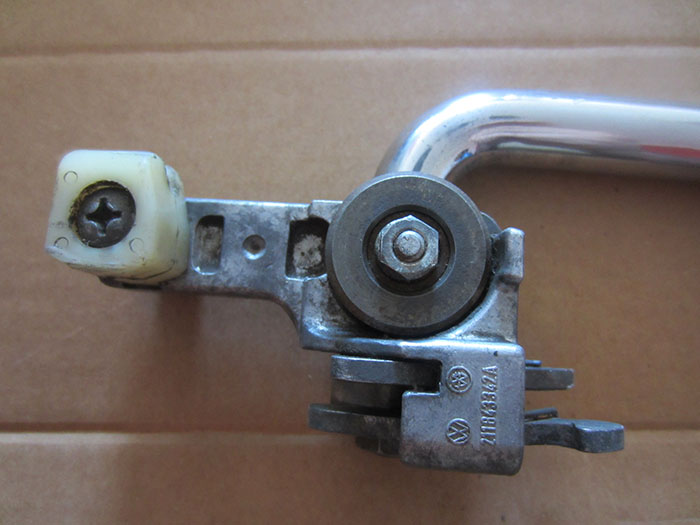

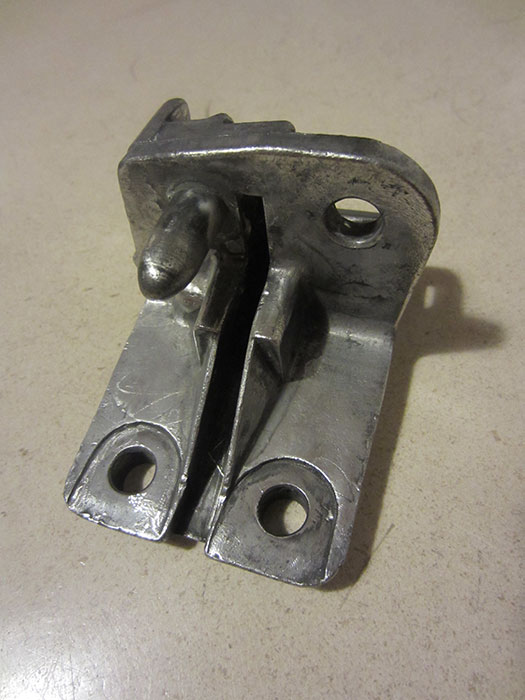

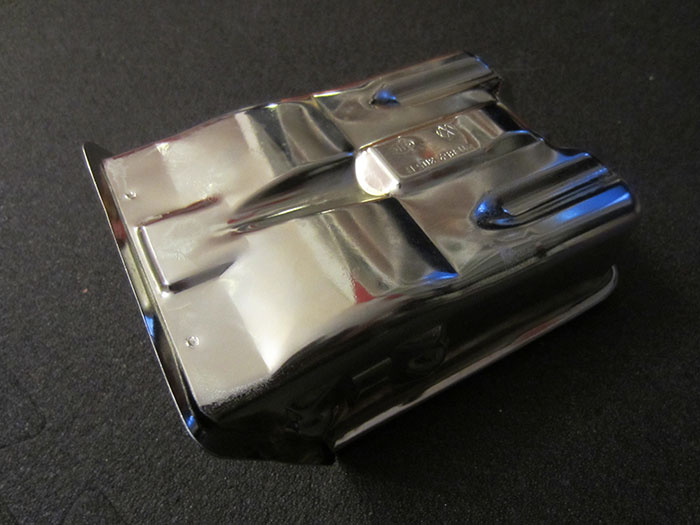

Meanwhile, these parts had been chromed and were waiting to be mounted in the right place:

Meanwhile, these parts had been chromed and were waiting to be mounted in the right place:

Similar threads

- Locked

Parts For Sale

now sold: 1600 engine for sale (august 2023)

- Replies

- 8

- Views

- 926

Vehicle For Sale

1971 T2a Double Cab Pick Up

- Replies

- 0

- Views

- 572

- Replies

- 0

- Views

- 1K

Vehicle For Sale

1968 LHD Turret Top Camper - 1903cc

- Replies

- 3

- Views

- 1K

Vehicle For Sale

1969 VW T2 Early bay - UK RHD - £13,750 ono

- Replies

- 2

- Views

- 1K