I spent a couple of hours inside the garage but when I went outside and looked north, there were two forest fires starting at the same time, in the same mountain but again, pretty far one from the other:

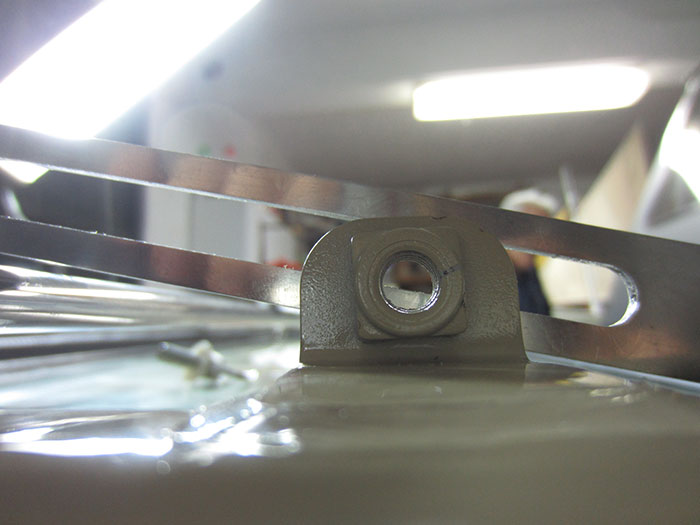

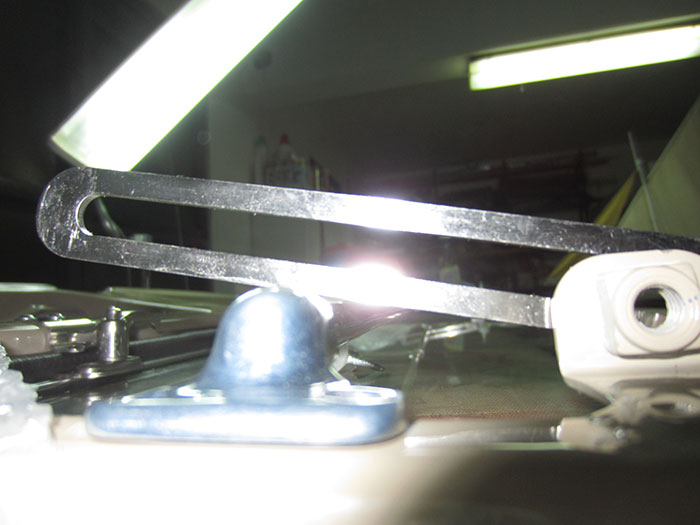

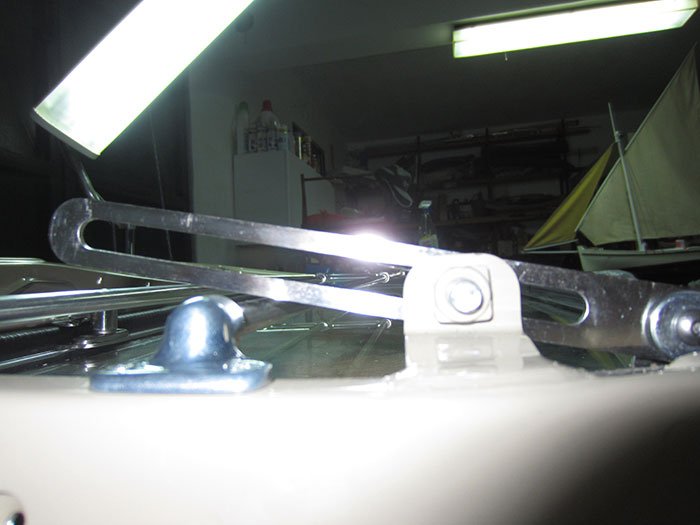

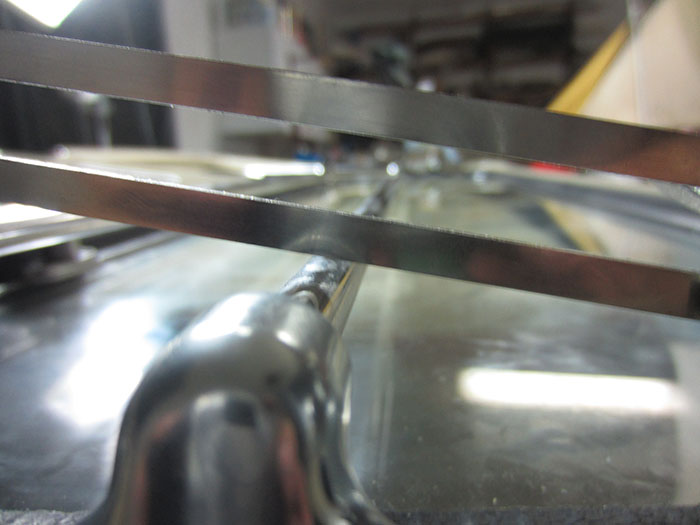

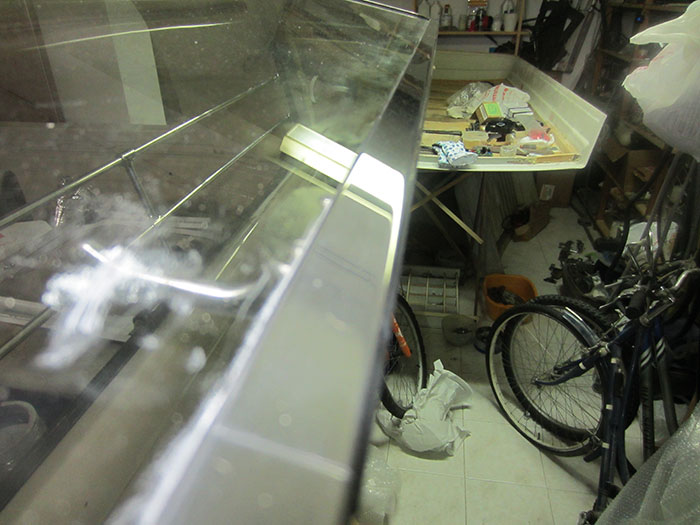

Meanwhile and although I had never made an repair like this or even worked with carbon fiber, I ended the repair on the windsurf board:

Meanwhile and although I had never made an repair like this or even worked with carbon fiber, I ended the repair on the windsurf board: