Valentine Won

Well-known member

Hope you had a good wkend mate  looks a bit wet

looks a bit wet

Bundy said:Certainly was wet at times! :lol:

Gotta say, Justin's install is very neat and the sound it makes is awesome 8)

Remon T2a said:That is one cool engine-swap.

Never heard of the corvair-engine. Sounds like a smooth one with that magical-6-sound.... 8)

What did you have to chance to fit the engine? Throttlecable? tinware? belhousing? Heating? Enginesupport? long or short gearbox?

What I see is that Dodge6X6 has an extra couple of vents for cooling....how is yours with cooling?

StuF said:Awesome work as usual Justin, cant wait to hear it purr this weekend at DATC!

Looks like a brilliant engine to have in the rear of a bus!

creationblue said:I must point out that Corvair engines run 'backwards' and if your using the PowerGlide auto tranni this is no problem, but if you want to use the VW manual then the motor needs to be reversed. This was done using a reverse cam, meaning it now turns the correct way for a Vdub 8)

squareweave said:Could you not just flip the ring and pinion in the transmission instead?

creationblue said:Remon T2a said:That is one cool engine-swap.

Never heard of the corvair-engine. Sounds like a smooth one with that magical-6-sound.... 8)

What did you have to chance to fit the engine? Throttlecable? tinware? belhousing? Heating? Enginesupport? long or short gearbox?

What I see is that Dodge6X6 has an extra couple of vents for cooling....how is yours with cooling?

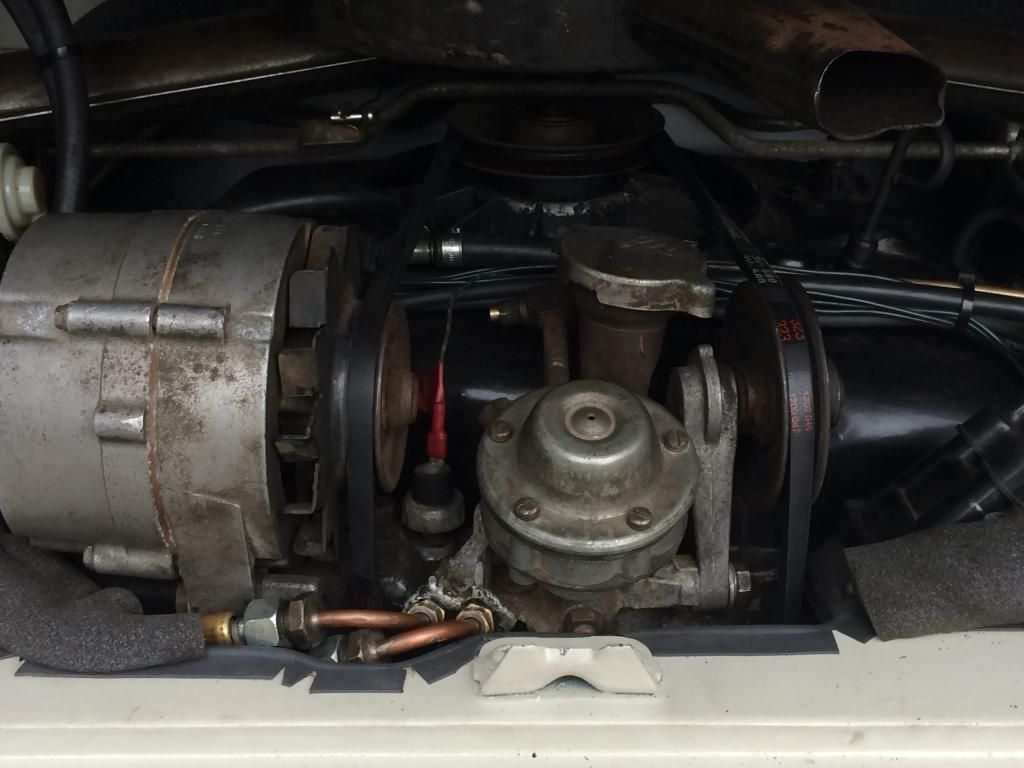

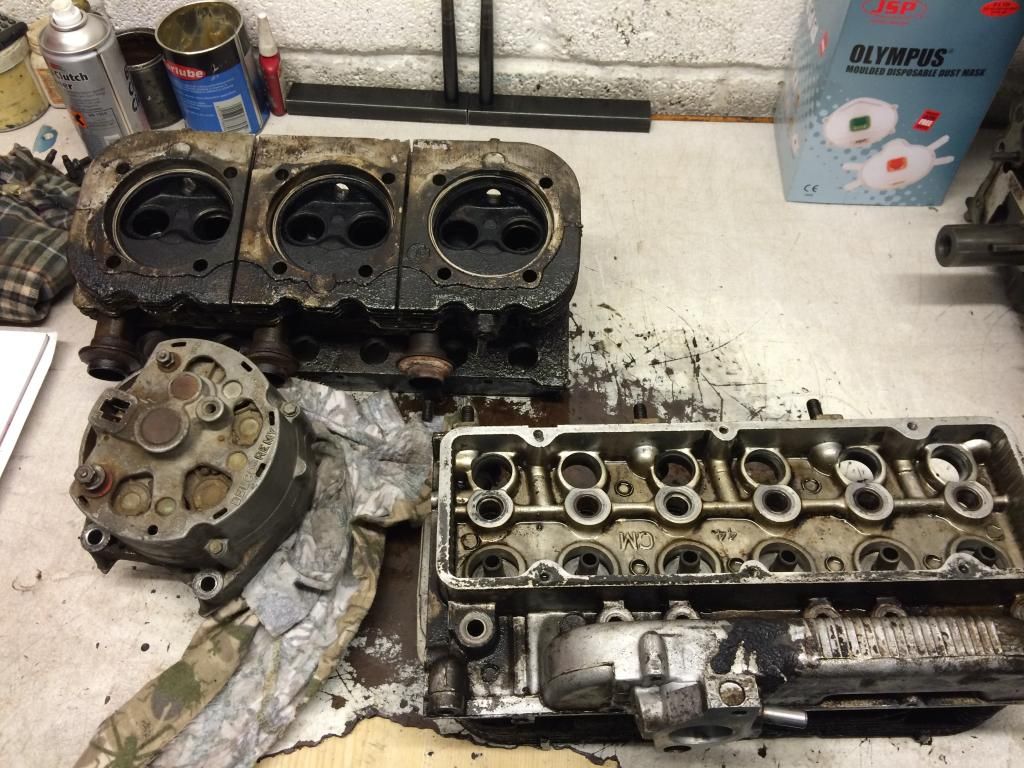

Hi, it's a fairly easy swap actually, it uses a Clarke adaptor, and mates right up to a 6rib late box, which was modified to fit a T1 engine in the normal ways. It has a modified Corvair flywheel with a VW 6v ring gear (different # of teeth to a 12v), so I'm running a 6v starter to suit. The clutch is stage1 KEP, all standard stuff.

I must point out that Corvair engines run 'backwards' and if your using the PowerGlide auto tranni this is no problem, but if you want to use the VW manual then the motor needs to be reversed. This was done using a reverse cam, meaning it now turns the correct way for a Vdub 8)

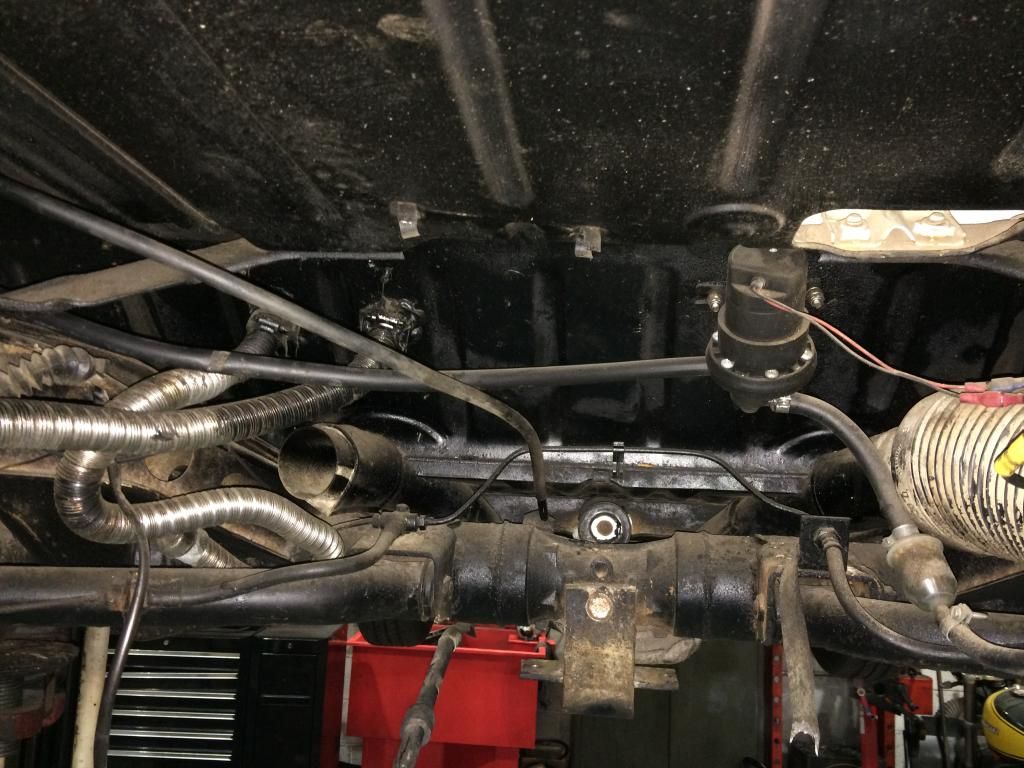

The difficult bit was designing an engine bar, so I kept it simple and used the standard early engine mounts, then fabricated a cradle picking up the corvair mounts on the back of the engine.

The throttle cable luckily was inch perfect and matched the corvair linkage, tho this will change when I fit Webers. I made the tin and used a late bay seal to fill the gaps. The rear valance is the only body mods needed.

The cooling on this is fantastic, the fan pushes air out the back via two 'exhausts' so even when stationary there is little chance of the hot air rising into the engine bay. No heating at the moment but I will make some adaptors to connect the heating ducts from the engine to the buses heating tubes. I will remount the oil filter under the bus when it comes out in the winter but for now I'm just running it. 8)

Bluesnailman said:Looks great! On fuel tanks I kind of decided last year after cleaning my tank that I was only going to use super unleaded, as no ethanol and no water attracting stuff.

I didn't last long as my fuel sender stopped working so I was forever forgetting my miles since last full and overcome with panic would seek out the nearest station and buy whatever they had. From now on though...... Change timing by 1.5deg (I think) and it's running on super for a couple of months. Not sure I'll get corvair power out of it though

Enter your email address to join: