So, created this thread almost 4 months ago and will now update on progress.

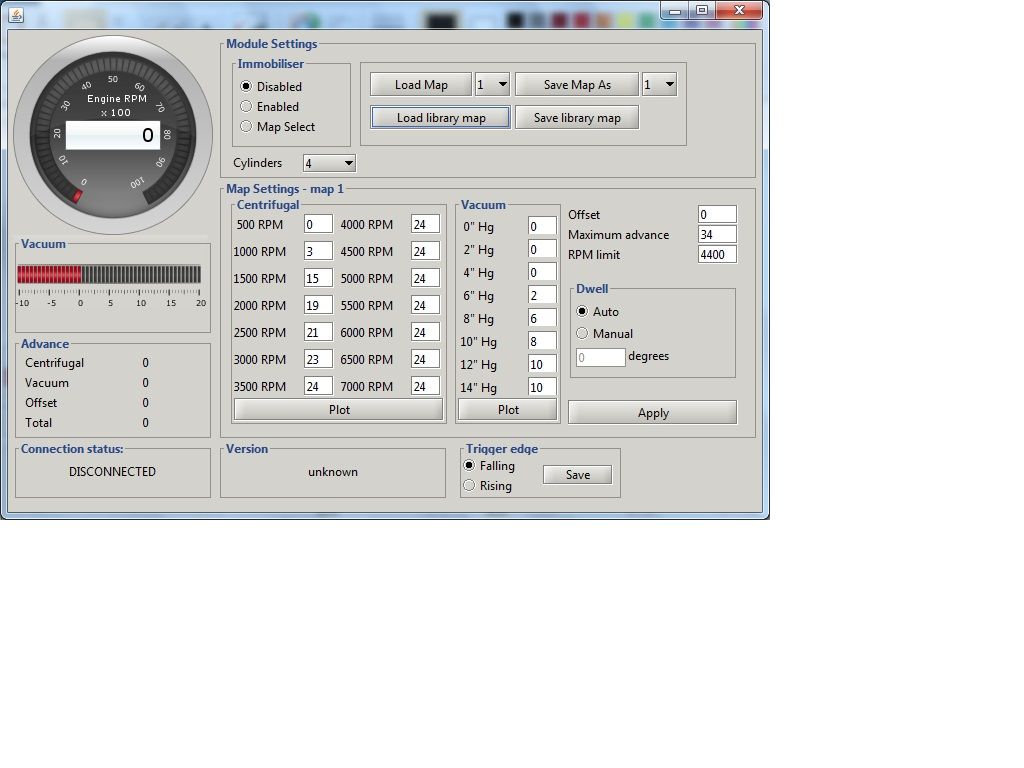

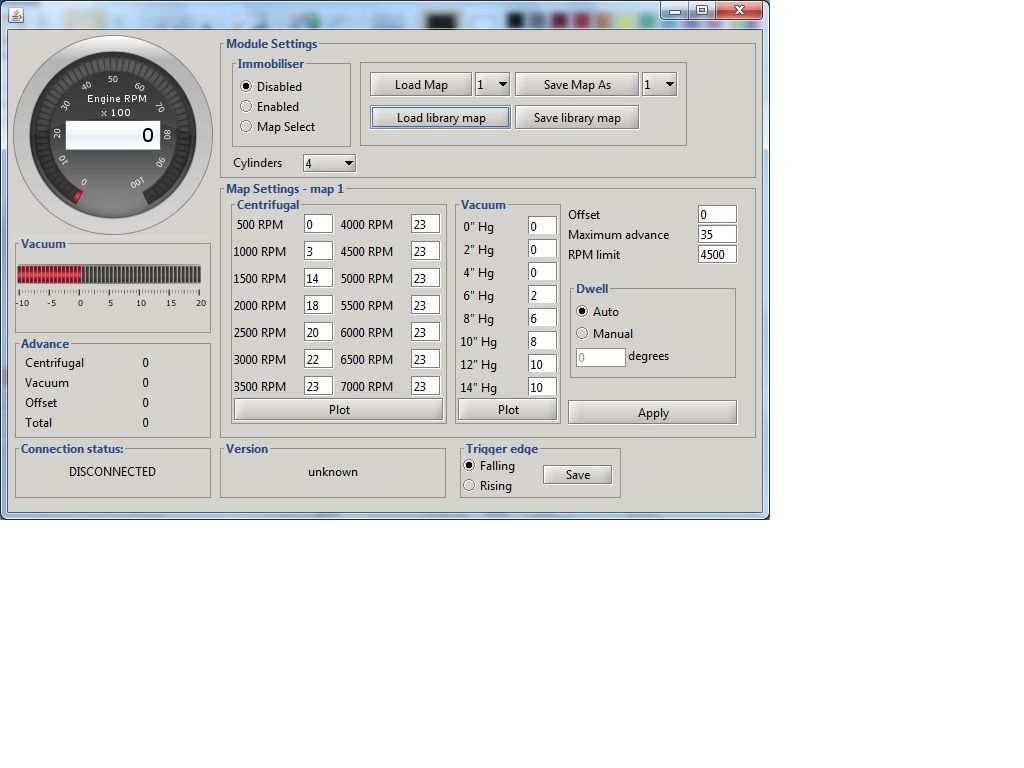

Took a bit longer than expected to get my gearbox back, so only got the engine in just after christmas. Done a fair bit of tweaking since using the amethyst module.

I hope this thread will not only provide an insight into the Aldon module, but should also provide some guidance on timing curves using other mappable systems such as the Accuspark Stealth Black Box and 123 Tune distributors. It may also be helpful for those writing custom maps for Megajolt, Megasquirt, Nodiz and CB Performance black box systems, although those systems provide additional timing map flexibility/complexity which I will not be fully detailing in this thread.

I'll start with my engine specs so the thread provides all the detail if anyone looks this up in the future..

Engine:

Stock case

Stock crank

Stock cam

33/30 Dual Port 043 Mexican FI heads, mildly polished ports.

CB performance 1.25 ratio rockers on bolt up shafts

Stock valve springs + pushrods

Twin Weber 34 ICTs, 57 idles + 140 mains, F6 emulsion tubes. 6mm balance pipe between manifolds

CSP bellcrank linkage

CB Performance Maxi 3 oil pump

1/2" Aeroquip hose with An/JIC socketless/push-fit fittings.

Remote filter head + wax stat feeding a Mocal 13 row oil cooler with under chassis scoop.

Facet posi-flo fuel pump & Malpassi filter king set at 3 psi.

Stock heater tubes

Custom stainless steel 4 into 1 exhaust by STG Performance

Ignition:

009 distributor with advance weights removed and plate welded solid.

Compu-fire electronic ignition module

Standard coil, cap & rotor.

Mr.RetroLeads(eBay) performance silicone HT leads

NGK BR6ES spark plugs

Aldon Amethyst mappable ignition module, AM03 model with Vacuum advance MAP sensor.

Gearbox:

CA code 3 rib, with 4.57 ratio ring and pinion. Driving 14" wheels with 195/70 R14 tyres. Not entirely relevant to the ignition module, but added for completeness and I'll upload a spreadsheet later on that calculates RPM at chosen speeds in certain gears etc.

Fuel:

Premium, Shell/BP/Esso 95 ron unleaded, no additional additives.

So, I'll start with the wiring... The instructions supplied with the Aldon Amethyst unit are not entirely clear.

Thick. Black - Earth

Red - Coil +ive or switched ignition (fit inline fuse)

Yellow - Coil -ive

Green - Petronix/Aldon/Powerspark/Compufire etc. black wire.

Thin black - map select or imobiliser wire (not used in my set up)

Petronix/Aldon/Powerspark/Compufire red wire - Coil +ive.

Mounting :

Preferably away from any significant sources of interference, heat and vibration.

I have mounted it in the top left hand corner of my engine bay, on the side of the spare wheel well with countersunk bolts and thick double sided foam for additional support and vibration absorption.

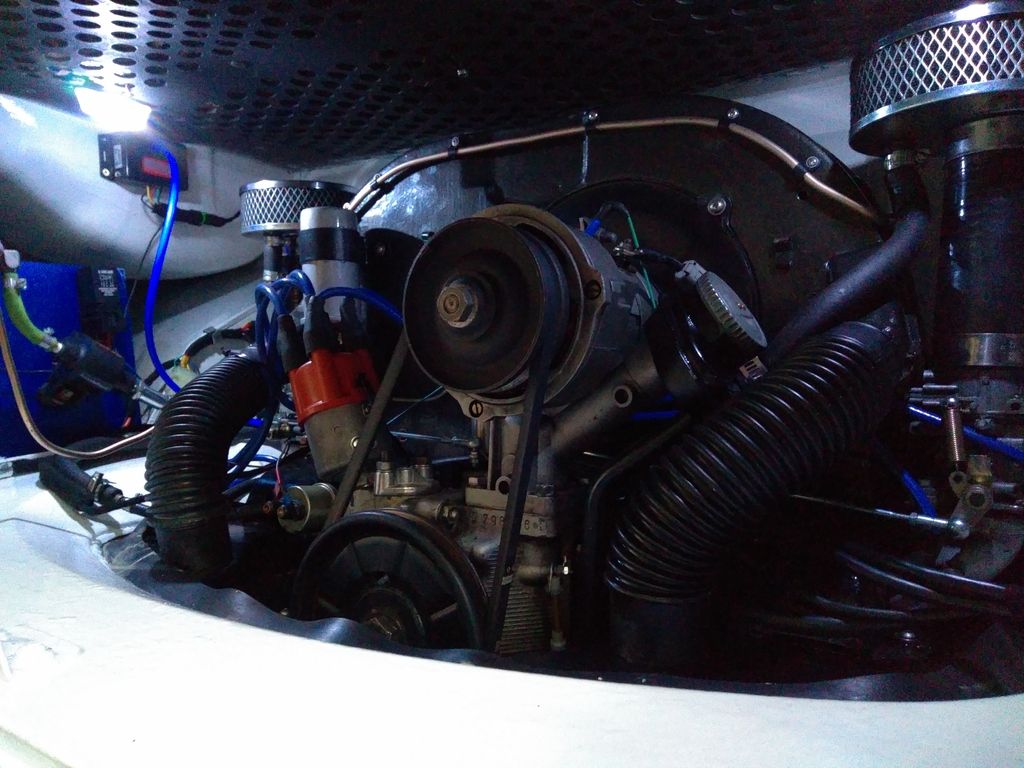

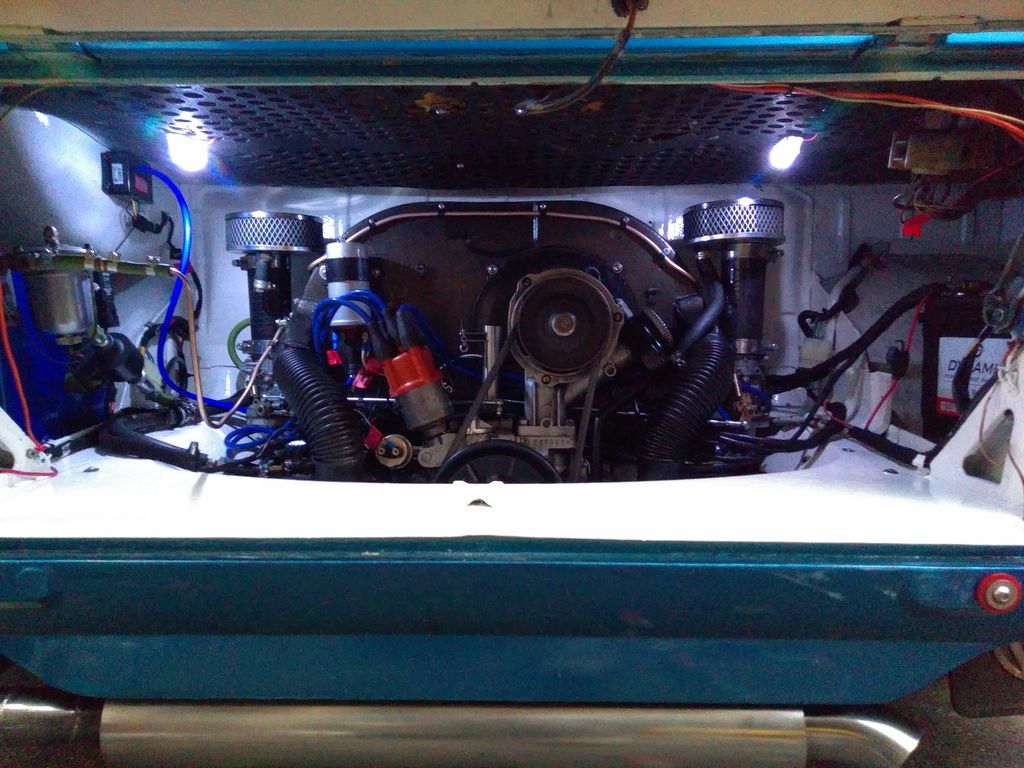

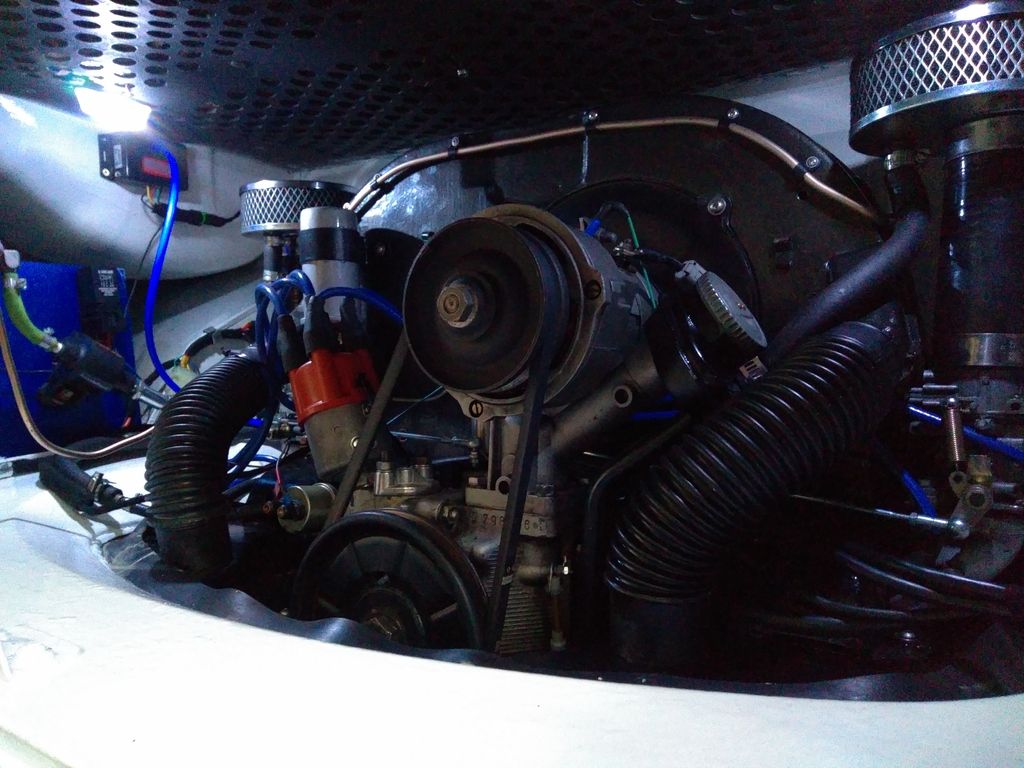

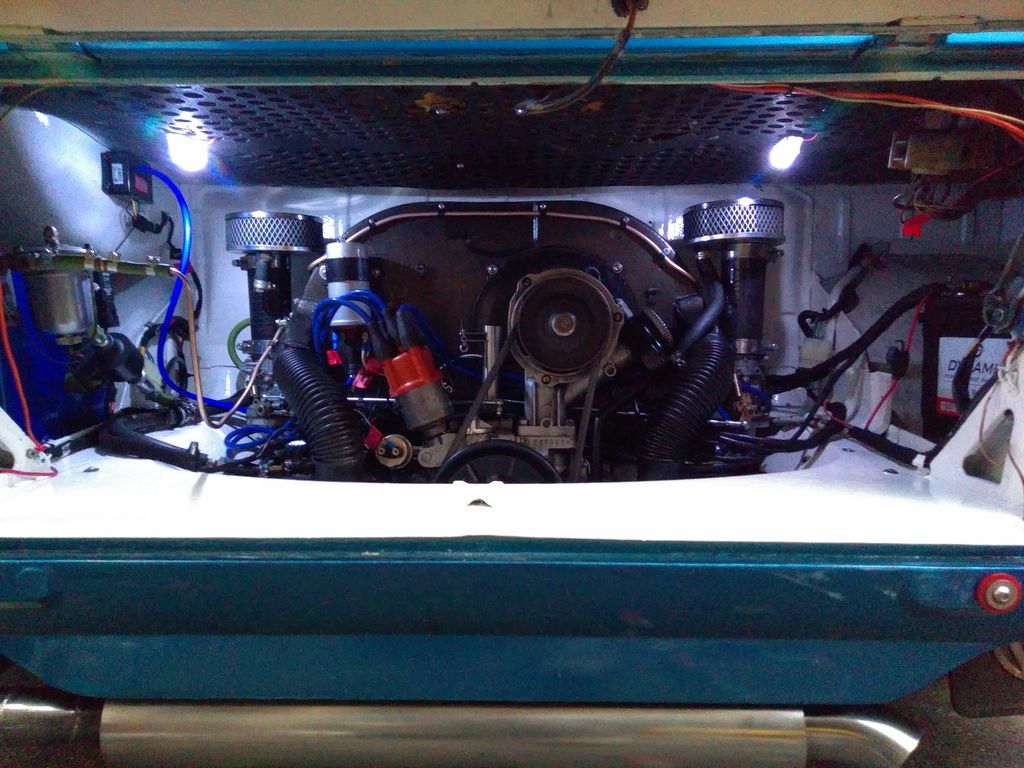

Picture 1 - Engine installed with Aldon Amethyst module.

Picture 2 - Engine installed with Aldon Amethyst module

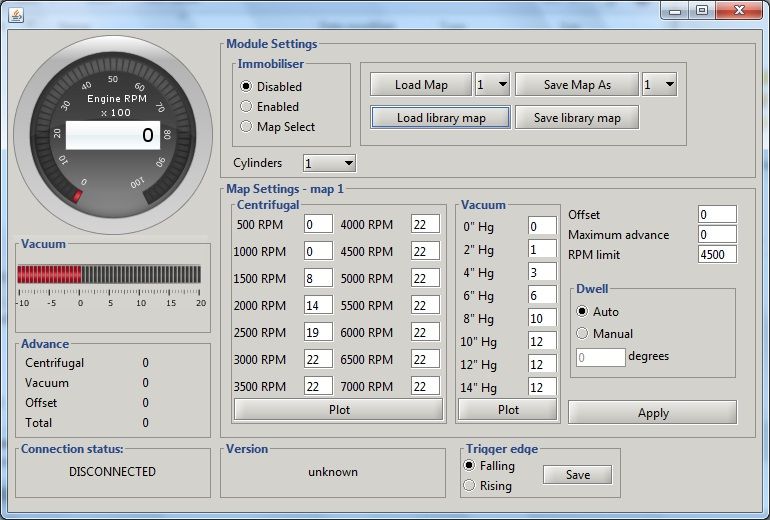

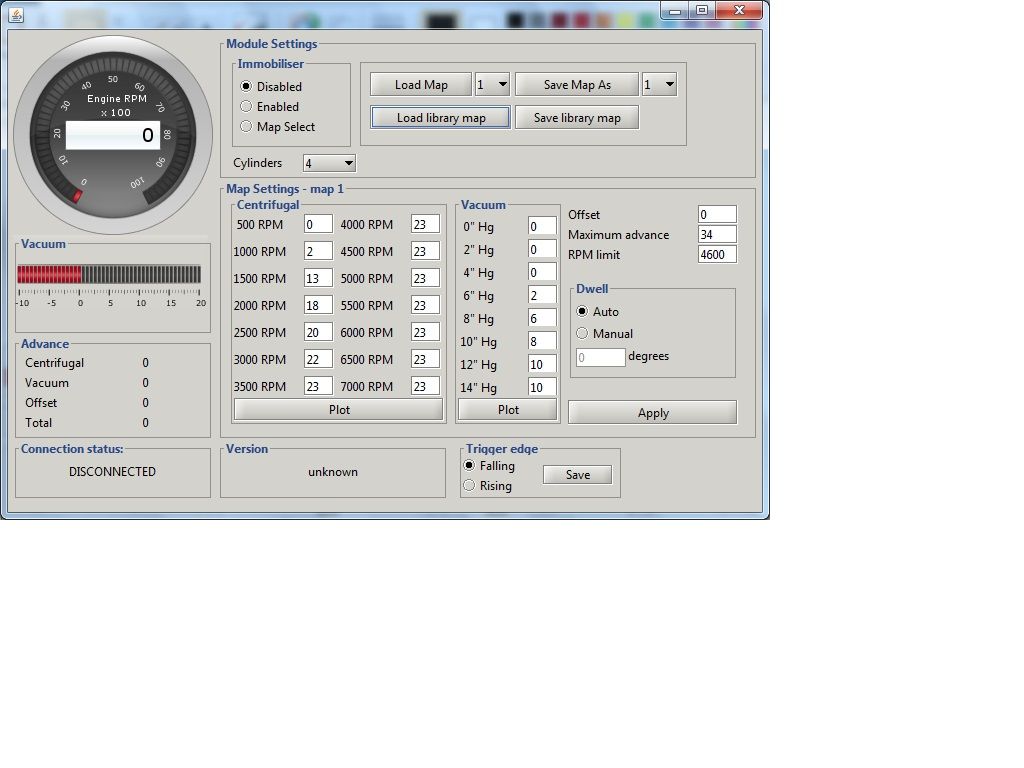

I will upload the timing curve I started with tommorow; along with the revisions made between then and now, with the reasonings behind each change. The basic/initial curve was derived from stock VW distributor curves, 4cyl Porsche distributor curves, some custom ignition maps from The Samba + ideal curve calculations.