- Joined

- Jun 11, 2013

- Messages

- 636

- Reaction score

- 4

- Location

- Leeds

- Year of Your Van(s)

- 1971

- Van Type

- Microbus

- M-codes

- 095 508 697 A01

I've been fitting and sorting out an engine for my bus for the last week. I started it up today and its burning oil, running 65psi oil pressure at cold idle (over 100 psi at 3000 rpm) and pissing oil out of the bell housing.

I replaced the flywheel oil seal in the engine with a dual lip version before I put it in the bus. End float on crank is 4 thou.

I have also had the heads off to polish the inlets and exhaust ports, fitted new exhaust valves all round. All the barrels, rings and pistons looked OK, barrels still had clear honing marks.

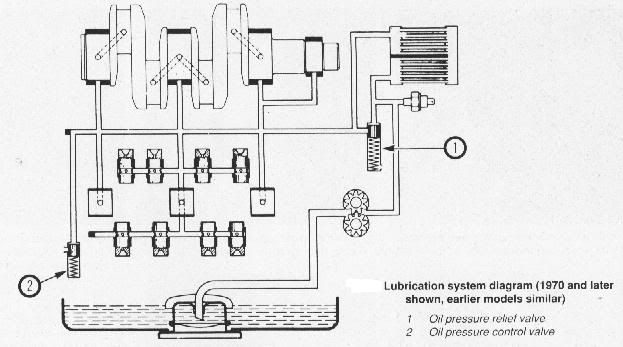

Oil pump is a CB Maxi 3 hosed up to Golf TDI oil filter and then back to the case. Oil is 5w40 fully syn.

Am missing something obvious here? What the hell has happened with this engine.

Could the high oil pressure be contributing to any of the other engine issues? Or am is it just blowing past the rings and out the flywheel seal.. There is no leak at the pulley end.

I

I replaced the flywheel oil seal in the engine with a dual lip version before I put it in the bus. End float on crank is 4 thou.

I have also had the heads off to polish the inlets and exhaust ports, fitted new exhaust valves all round. All the barrels, rings and pistons looked OK, barrels still had clear honing marks.

Oil pump is a CB Maxi 3 hosed up to Golf TDI oil filter and then back to the case. Oil is 5w40 fully syn.

Am missing something obvious here? What the hell has happened with this engine.

Could the high oil pressure be contributing to any of the other engine issues? Or am is it just blowing past the rings and out the flywheel seal.. There is no leak at the pulley end.

I