- Joined

- May 17, 2021

- Messages

- 359

- Reaction score

- 280

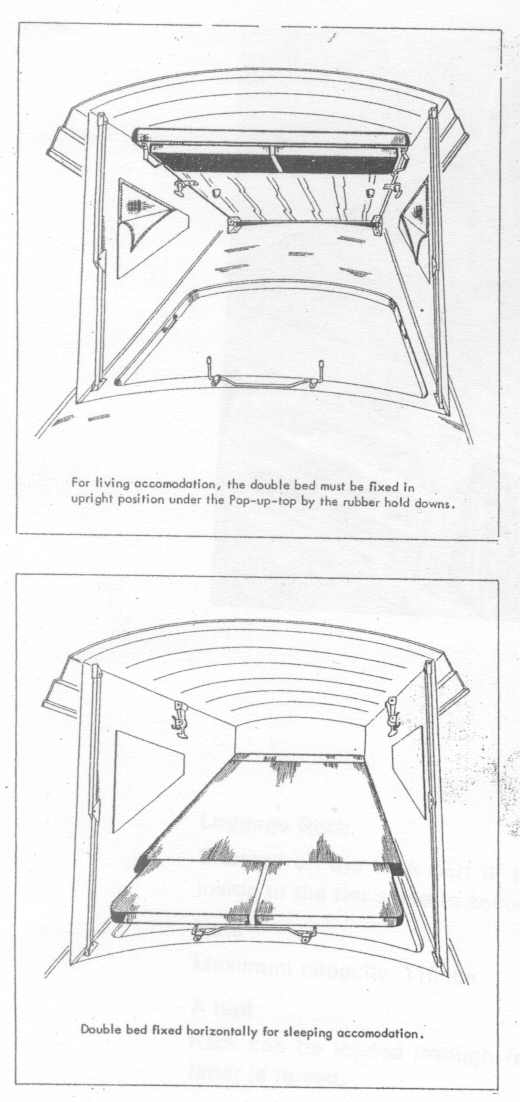

So I eventually assembled a bed to the original spec using various bits from NLA VW. I bought the main roof bed kit off Facespace and it was missing the hinge bracket so my friend made an identical one at his shop.

Installation tomorrow at some point.

I'm really pleased with it. It looks almost factory.

Installation tomorrow at some point.

I'm really pleased with it. It looks almost factory.