Hey guys, I've torn down the engine from my new van, and I'm seeing scored bearings and crank journals, as well as a previous line bore (.5mm/.020"). I want to drill and tap the case for a full flow setup, and minimise any future wear.

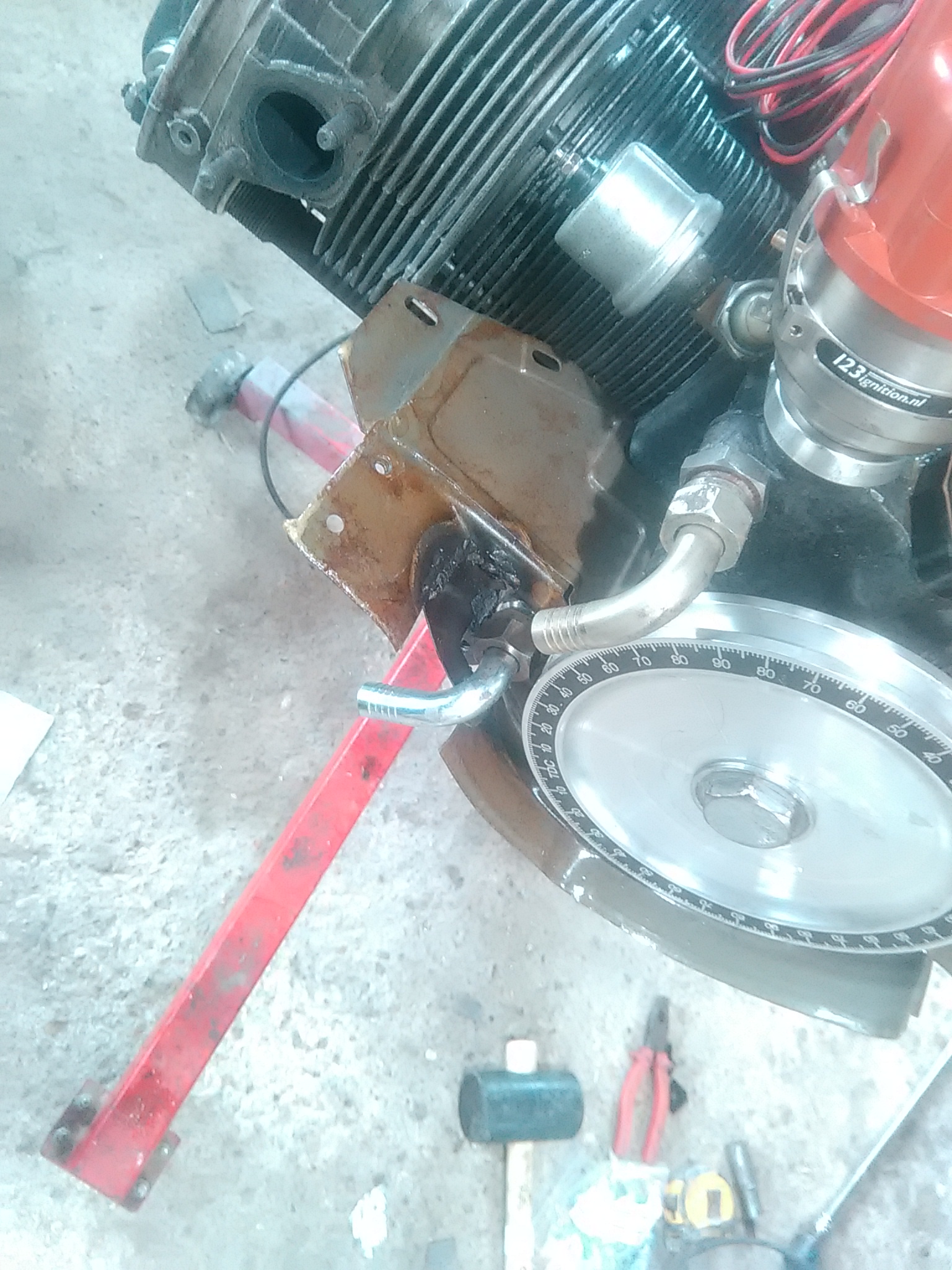

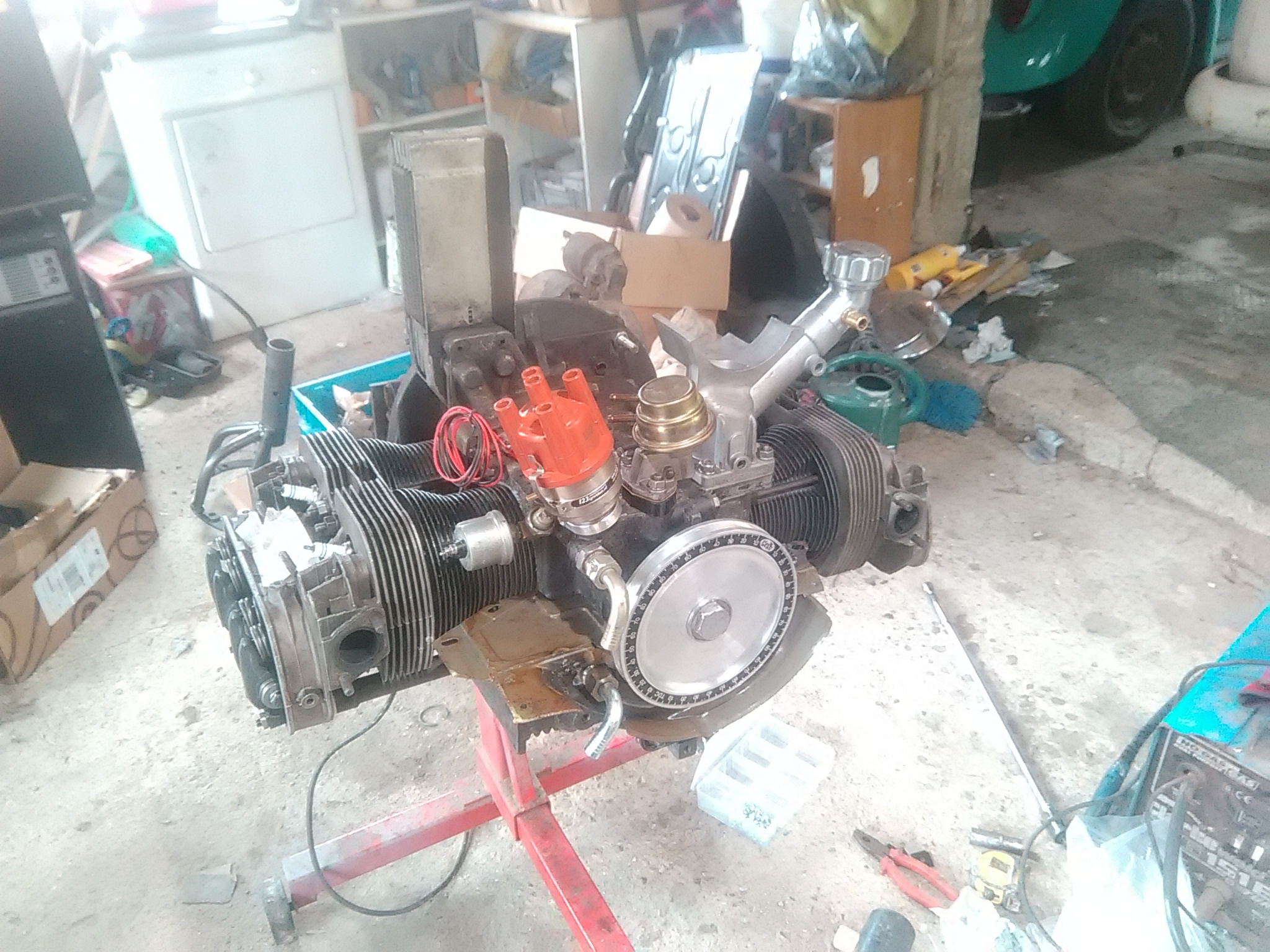

The catch is that the engine uses an adapter plate for mounting to the moustache bar (bug engine I guess? AE code), so I can't use the most common method of creating an out pathway from the pump cover.

Looking at the lubrication diagram, it looks like I can tap an out pathway where the usual setup oil return line would go, and add tap my return into the plug foward and above of the oil pressure switch, and still utilise the oil pressure release valve.

It looks like full flow setups on type 3 engines use this method due to their engine support bar clearance to the oil pump, but will this method cause any issues? Are there any major differences with the oil flow from the pump cover method? How would the galley be plugged (like the pump gets plugged) to direct the oil externally to the filter first? I'm using this thread as my reference: https://www.thesamba.com/vw/forum/viewtopic.php?p=7890596, about half way down (post by richparker).

My van is a 72 crossover, and I'm going from 1584cc to 1776cc.

Cheers

The catch is that the engine uses an adapter plate for mounting to the moustache bar (bug engine I guess? AE code), so I can't use the most common method of creating an out pathway from the pump cover.

Looking at the lubrication diagram, it looks like I can tap an out pathway where the usual setup oil return line would go, and add tap my return into the plug foward and above of the oil pressure switch, and still utilise the oil pressure release valve.

It looks like full flow setups on type 3 engines use this method due to their engine support bar clearance to the oil pump, but will this method cause any issues? Are there any major differences with the oil flow from the pump cover method? How would the galley be plugged (like the pump gets plugged) to direct the oil externally to the filter first? I'm using this thread as my reference: https://www.thesamba.com/vw/forum/viewtopic.php?p=7890596, about half way down (post by richparker).

My van is a 72 crossover, and I'm going from 1584cc to 1776cc.

Cheers