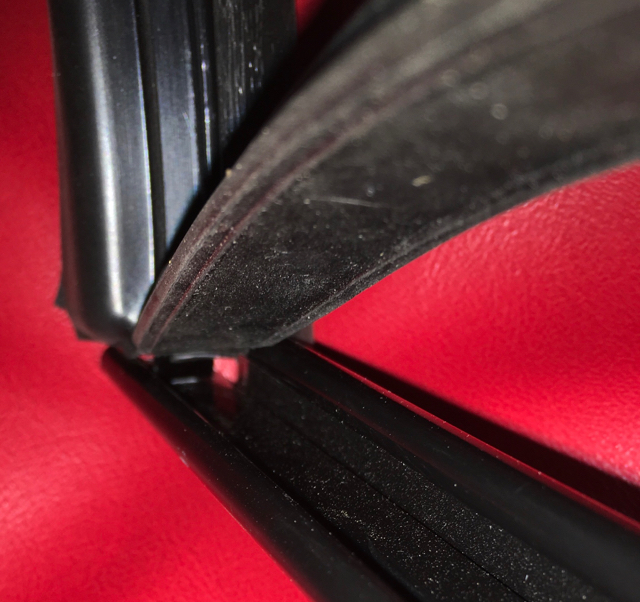

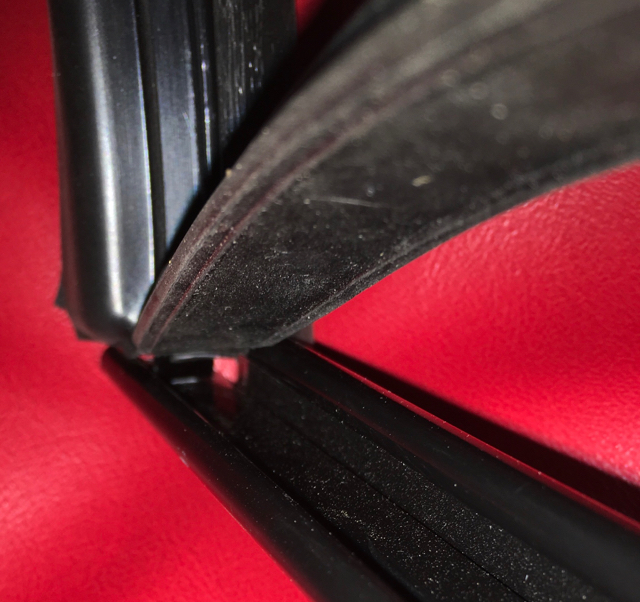

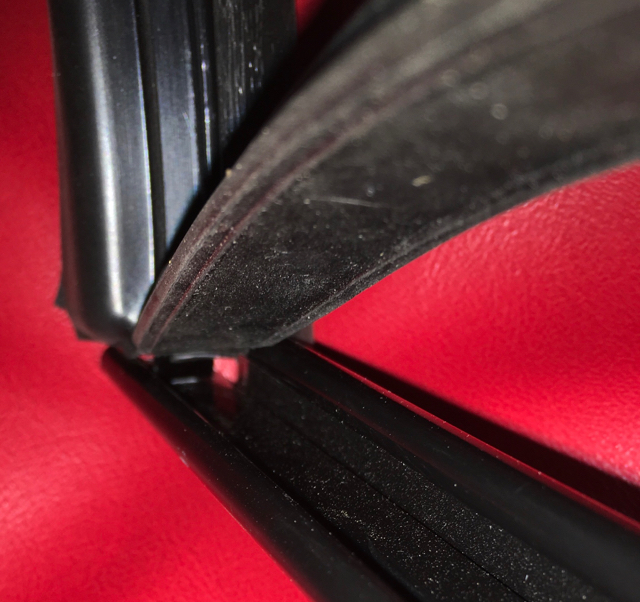

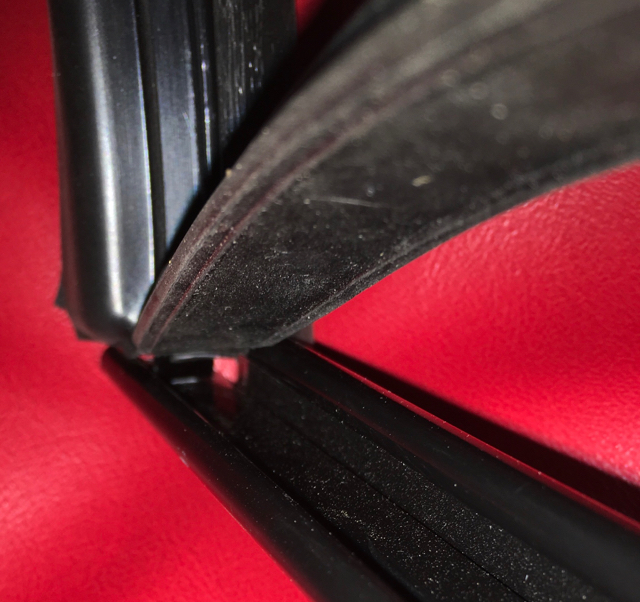

Does anyone have any advice on how to get the vertical section of rubber in the groove? I have riveted the two parts of the metal frame together and partly installed the rubber on the "C" section but the last bit is beating me!

WD40 mate. Get as much of the larger side of the rubber hooked in as possible and then ease the smaller side under the lip with a really blunt flat bladed screw driver. Being really careful not to slip and damage yourself, the rubber or the channel. Once you get one bit started work along and it will start to slip in nicely. If it's a new frame and new rubber good luck getting it into the van. They can be a nightmare. Make sure you close the quarter light window before installing it a leave it closed during the whole process otherwise the frame may bend.Saercoed said:Does anyone have any advice on how to get the vertical section of rubber in the groove? I have riveted the two parts of the metal frame together and partly installed the rubber on the "C" section but the last bit is beating me!

ThanksJohnny said:I've got two bruised thumbs from trying the taller side first :lol: but everyone has there own methods

I found it easier to rest the frame on the straight edge with the glass fully open as a stand and shallow c section furthest from me (helps if you have another bod to hold the frame steady). This allowed maximum pressure and with less chance of scraping the paint off the vertical. Then with the taller c section I only had to push down for it to slip in place, the shallower c section had to go down and slide in.

I also found the new aluminum C frame was millimeters longer than the original and bending the tabs where the vertical was fixed to, helped when fitting the larger window in behind. We had the whole window assembly in and out a few times before we realised this was the only way to get the quarter light rubber to seat and fit flush to the body at the font side.

don't be afraid to give it a good tap to get the quarter light to fit as far forward as possible in the bus. The vertical upright with the c sections also has tabs that must fit over the bodywork of the bus its self before you start to push the whole quarter light forward. You will find a nick at the top of the frame aperture of the bus to allow this to slide in place. I should have took a few pictures but we were under pressure to get done for MOT (passed with no advisories).

Enter your email address to join: